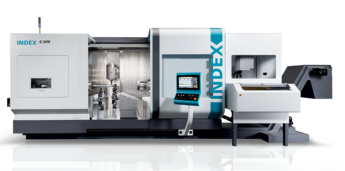

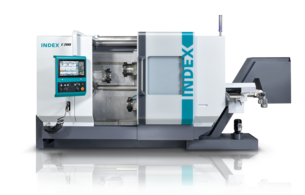

The innovative turn-mill center for high-performance

machining of large workpieces

Turning and milling – complete machining in new dimensions

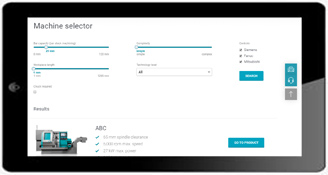

Machine highlights INDEX G400 / INDEX G420

Your benefits

- Identical main and counter spindles with spindle clearance D 120 mm

- Chuck D 400 mm

- Tool stock for up to 139 tools (INDEX G420)

- Sophisticated working area concept for turning lengths up to 1,600 mm / 2,300 mm and variable machining options

- High thermal and mechanical stability

- High dynamic response (rapid traverse rate up to 50 m/min)

- Chip conveyor can be used on the left and right

Wide range of parts

For applications in the automotive, aerospace or mechanical engineering sectors

Turret head

- Industry: Mechanical engineering

- Material: Steel

- D 273 mm x 76 mm

Flange

- Industry: Mechanical engineering

- Material: Steel

- D 178 mm x 120 mm

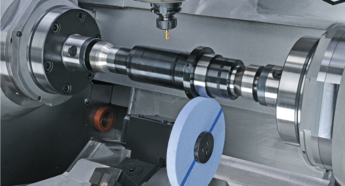

Shaft

- Industry: Automotive

- Material: Steel

- D 60 mm x 510 mm

Rotor carrier

- Industry: Aerospace

- Material: Steel

- D 140 mm x 285 mm

The INDEX G420 turn-mill center offers the best performance for customers from the mechanical engineering, automotive and aerospace industries, with high availability and process reliability – the complete solution when it comes to high-performance machining of large workpieces.

WE NEED YOUR CONSENT!

This content is provided by Youtube.

If you activate the content, personal data may be processed and cookies set.

Accept

WE NEED YOUR CONSENT!

This content is provided by Youtube.

If you activate the content, personal data may be processed and cookies set.

Accept

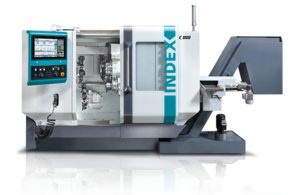

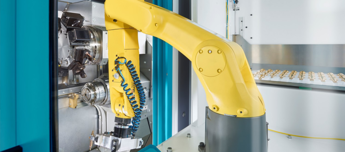

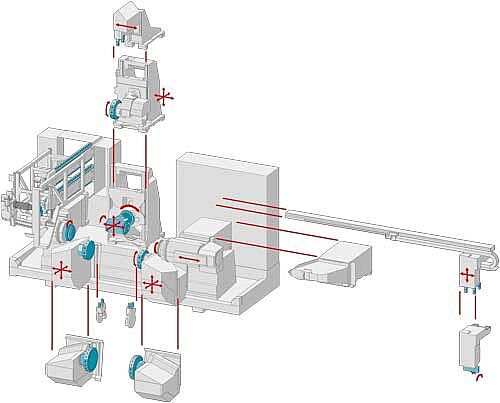

Integrated automation solutions for efficient production

The integrated workpiece handling unit is available as an option. It can be used for loading and unloading as well as for the removal of remnants and is suitable for parts weighing up to 25 kg and with a diameter of up to D 120 mm. The handling unit is equipped with 2 CNC axes that are operated from the machine control.

Further individual automation solutions, such as conveyor belts or robot handling with ancillary functions, can be integrated on a customer-specific basis.

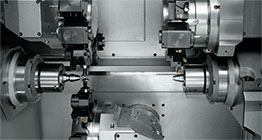

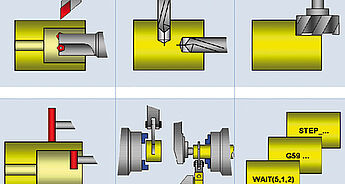

Complete machining based on a modular system

The INDEX G420 modular system offers a wide range of options. Up to 3 tool carriers can be integrated into the working area – all equipped with a Y axis. The working area offers ample space for machining any kind of workpieces. The working area can accommodate parts up to a length of 1600 mm / 2300 mm. The powerful main and counter spindles are designed for bar diameters up to D 120 mm and for chuck parts up to D 400 mm. Turret steady rests are available for machining long or shafttype parts.

Of course, the INDEX G420 is also capable of simultaneous 5-axis machining.

The ergonomic setup and operating concept was of great importance for the new design. All relevant components are easily accessible for operating and maintenance personnel. Optionally, an integrated 2-axis workpiece handling system matched to the machining processes can be used for loading and unloading the machine.

Control

Best performance for applications

in the aerospace industries