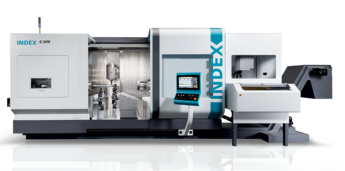

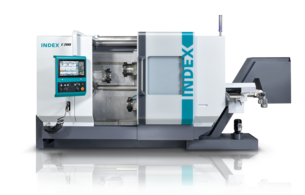

Dynamic multi-spindle machine

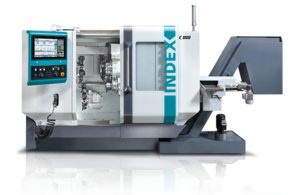

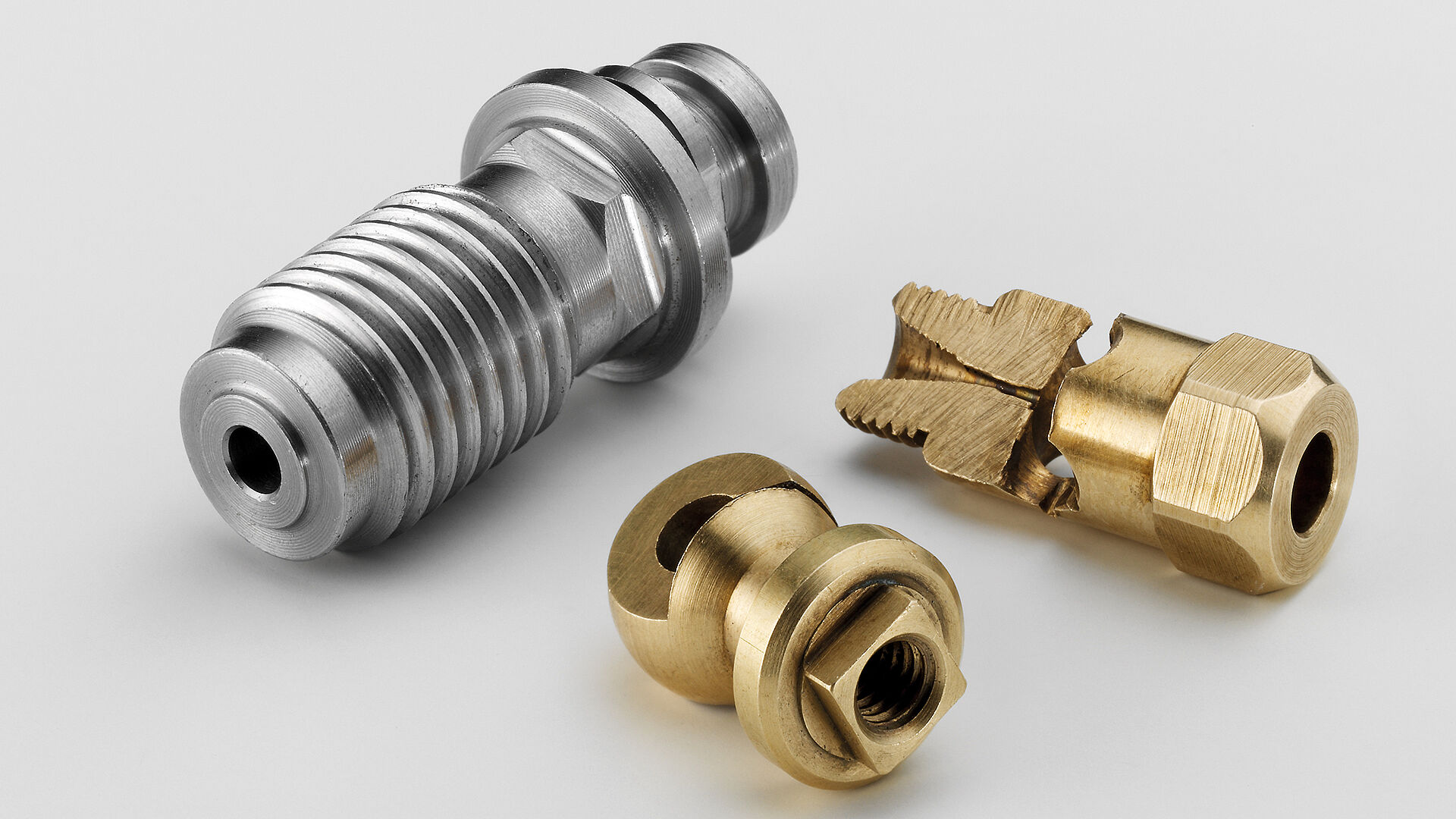

Shortest possible changeovers, ultra-high dynamics and lowest secondary times are the basis of minimal cost per part.

Machine highlights

Your benefits

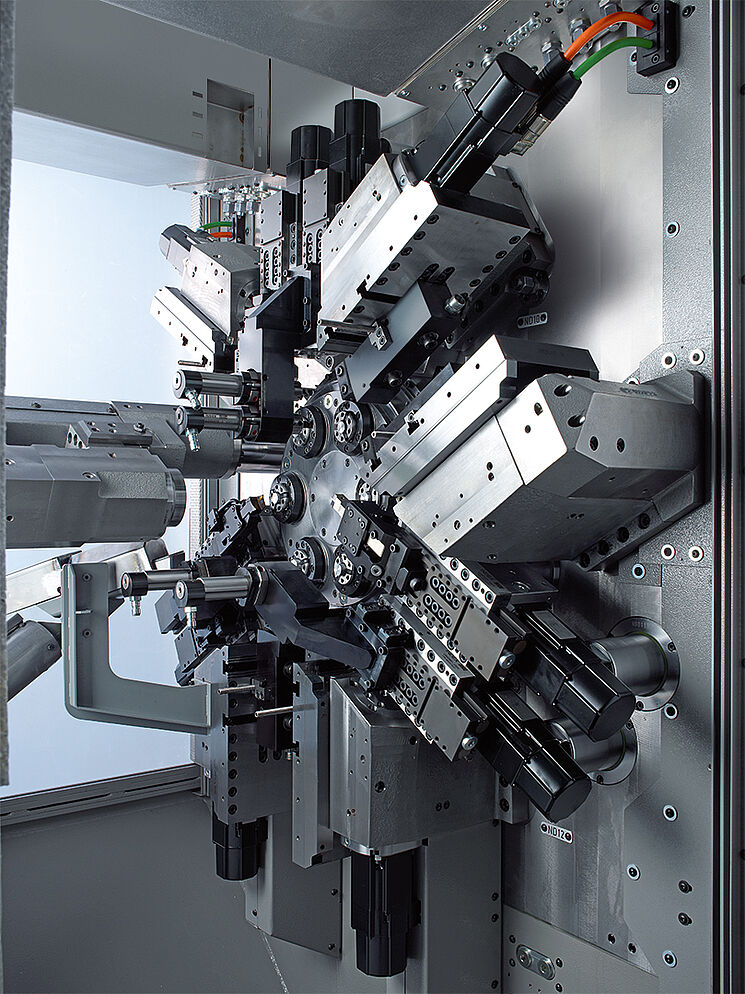

- Grooving slide for maximum cutting performance with minimum machining time

- Quick tool setup by INDEX W-serration

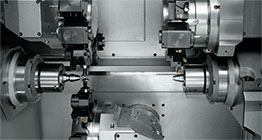

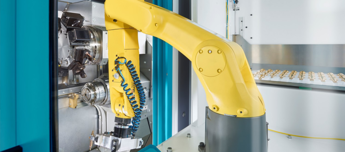

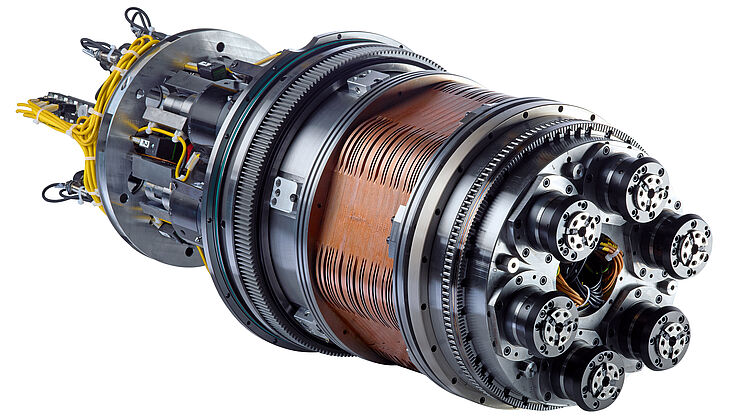

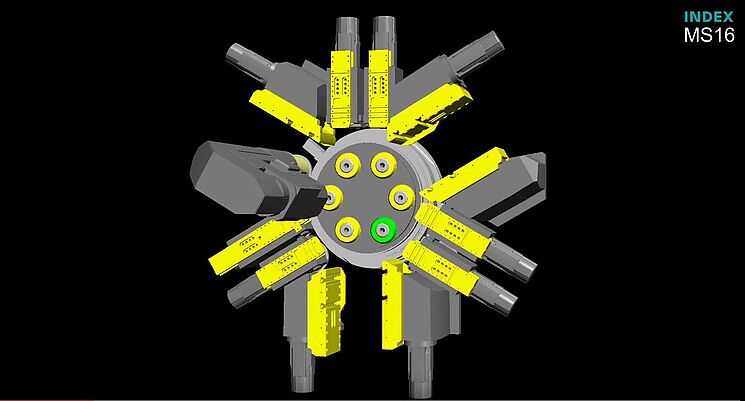

- Spindle drum with individual drives of the work spindles

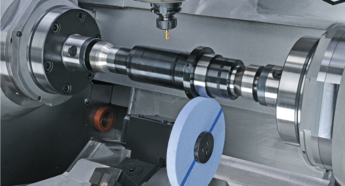

- Cross-slide for flexible complete machining

- CNC cutoff slide with extended stroke for rear end machining

- Highly dynamic synchronous spindle with extremely short acceleration and deceleration times

- Up to 22 mm bar diameter with version MS16-6 Plus

- Already included: the operating system iXpanel i4.0 ready with 18.5” touch screen and Siemens S840D sl

MS16-6 & MS16-6 Plus in focus

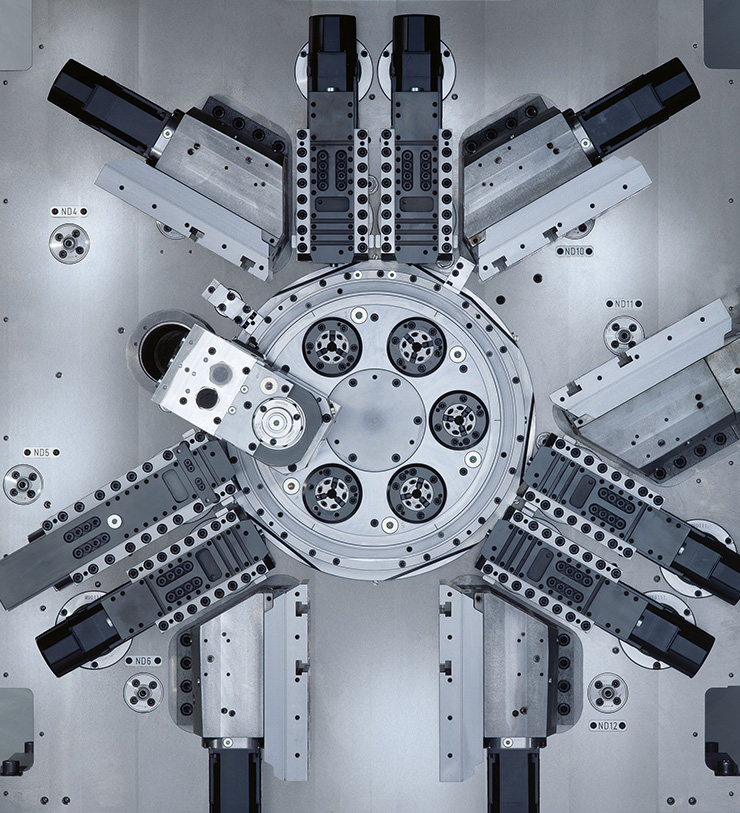

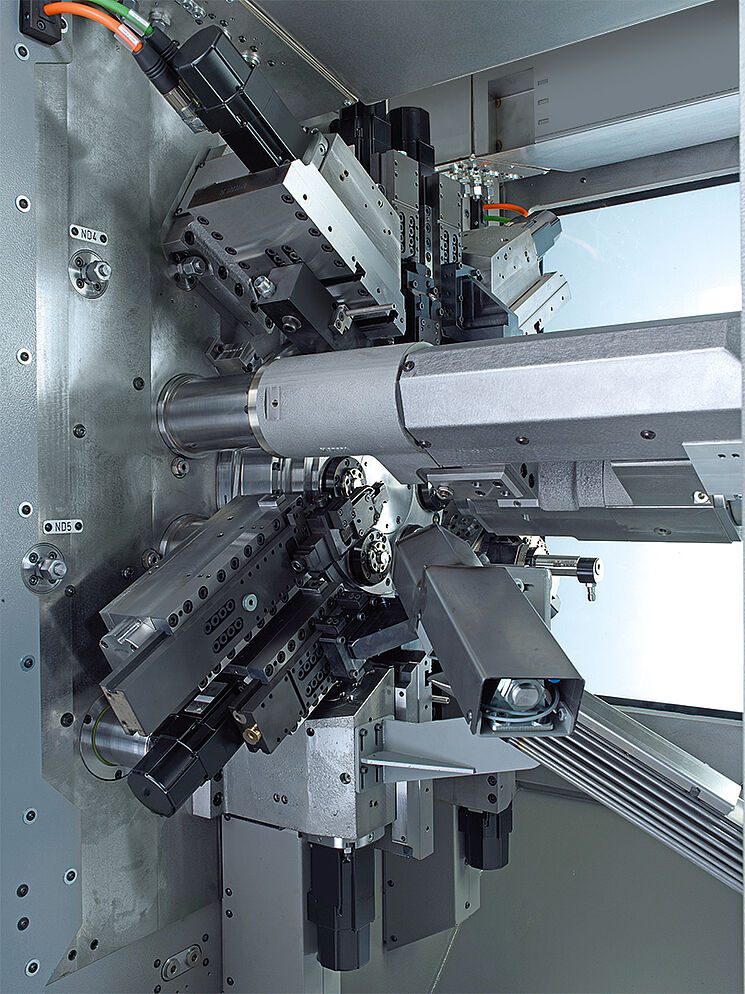

The machine design

With dynamic and diverse machining capabilities at low unit costs

- A maximum of 12 tool carriers with 1 or 2 travel axes

- Fast synchronous spindle for rear end machining

- Several tools per cross-slide possible

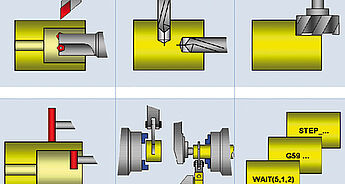

- Variable use of tool carriers, internal-external, stationary or live

- C-axis machining possible in every spindle position

- Polygon turning and other machining options

Extended version MS16-6 Plus

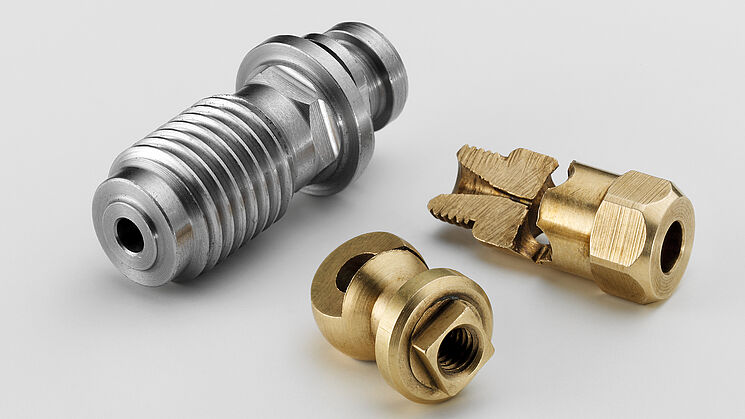

Diverse machining technologies

Milling

Milling with live tool, also in conjunction with C-axis mode (Transmit).