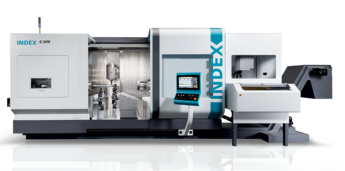

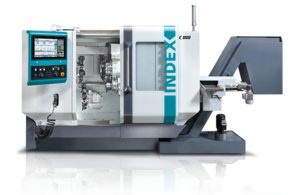

The innovative turn-mill center for high-performance

machining of large workpieces

Turning and milling – complete machining in new dimensions

Machine highlights INDEX G500 / INDEX G520

Your benefits

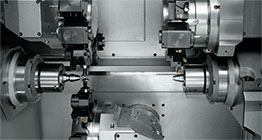

- Identical main and counter spindles with spindle clearance D 120 mm

- Chuck D 500 mm

- Tool stock for up to 139 tools (INDEX G520)

- Sophisticated working area concept for turning lengths up to 1,600 mm / 2,300 mm and variable machining options

- High thermal and mechanical stability

- High dynamic response (rapid traverse rate up to 50 m/min)

Wide range of parts

For applications in the automotive, aerospace or mechanical engineering sectors

Turret head

- Industry: Mechanical engineering

- Material: Steel

- D 273 mm x 76 mm

Flange

- Industry: Mechanical engineering

- Material: Steel

- D 178 mm x 120 mm

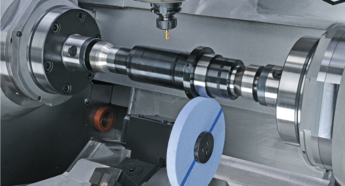

Shaft

- Industry: Automotive

- Material: Steel

- D 60 mm x 510 mm

Rotor carrier

- Industry: Aerospace

- Material: Steel

- D 140 mm x 285 mm

The INDEX G520 turn-mill center offers the best performance for customers from the mechanical engineering, automotive and aerospace industries, with high availability and process reliability – the complete solution when it comes to high-performance machining of large workpieces.

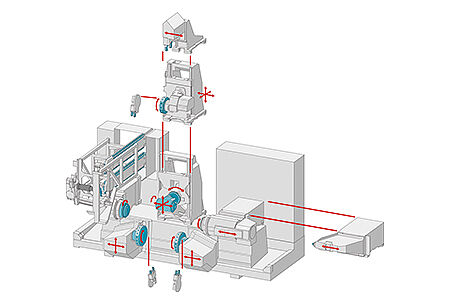

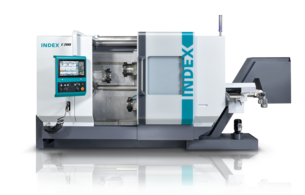

Complete machining based on a modular system

The modular system in this series offers a wide range of options. Up to 3 tool carriers can be integrated into the work area. The work area offers ample space to machine any kind of workpiece. The working range allows for parts up to 1,600/2,300 mm in length. The powerful main and counter spindles are designed for bar diameters up to 120 mm and for chucked part diameters of up to 500 mm. Turret steady rests are available for machining long or shaftshaped parts.

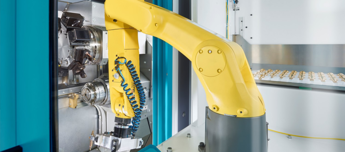

The INDEX G520 features a powerful motorized milling spindle capable of performing simultaneous 5-axis machining. The ergonomic setup and operating concept played a major role in the new design. All the relevant components are easily accessible for operating and maintenance personnel. The modular robot cell iXcenter is available for all machines in this series, for flexible feeding and discharging of blanks and finished parts.

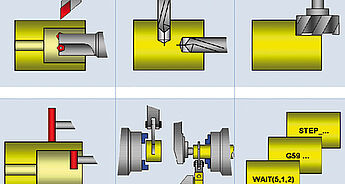

Control

Best performance for applications

in the aerospace industries

![[Translate to English (US):] [Translate to English (US):]](/fileadmin/_processed_/8/8/csm_dl_G420_closed_7d6942174f.png)