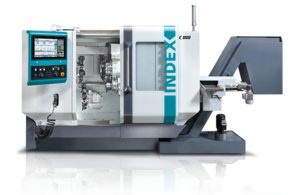

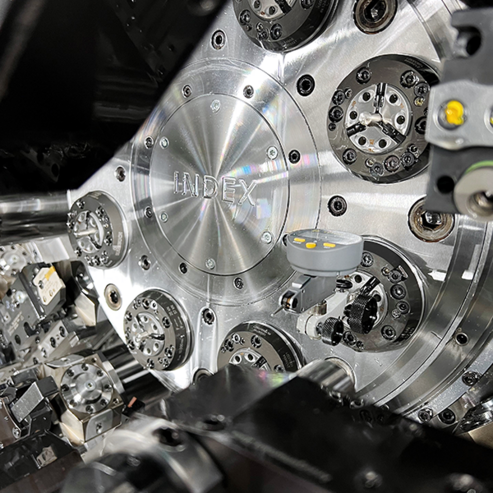

INDEX CenterMaster

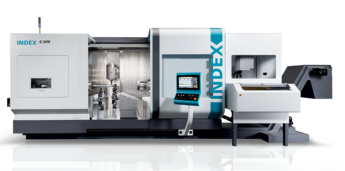

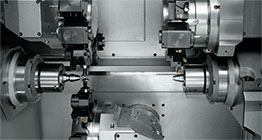

Centering drill holders in multi-spindle automatic lathes is a necessary but time-consuming and inconvenient task—or it used to be! With our newly developed INDEX CenterMaster, this task is practically child’s play: Based on a wireless dial gauge, a receiver installed in the control cabinet, and advanced mathematic software, the drill holders can be precisely aligned to the spindle—in less than five minutes!

Highlights

- Fast: Precisely aligning a drill holder on the center of the spindle takes less than five minutes.

- Ergonomic: Wireless data transmission dispenses with the laborious reading of the dial gauge.

- Reproducible: Reproducible results with a precision of < 5 μm are achieved independently of the persons involved.

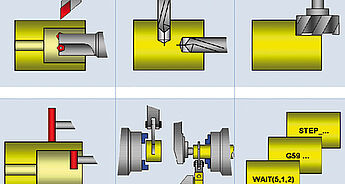

With our CenterMaster, we have developed a solution that lets machine setters center drill holders very easily and quickly, as well as with great precision and reproducibility. The hard-ware required is a wireless dial gauge and a corresponding receiver, which is integrated in the control cabinet and communicates with the control. However, the centerpiece of our setup assistance is the CenterMaster app. It is based on software that we have developed that can be started from the control unit of the machine—the INDEX iXpanel. It ensures that the measured positions are transferred from the dial gauge to the control with a reproducible

precision of < 5 μm.

INDEX CenterMaster

WE NEED YOUR CONSENT!

This content is provided by Youtube.

If you activate the content, personal data may be processed and cookies set.

Accept