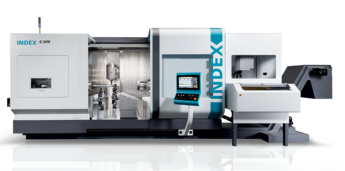

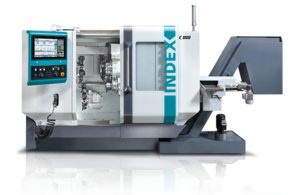

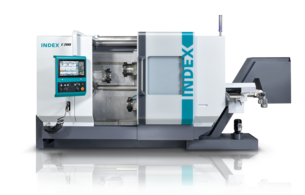

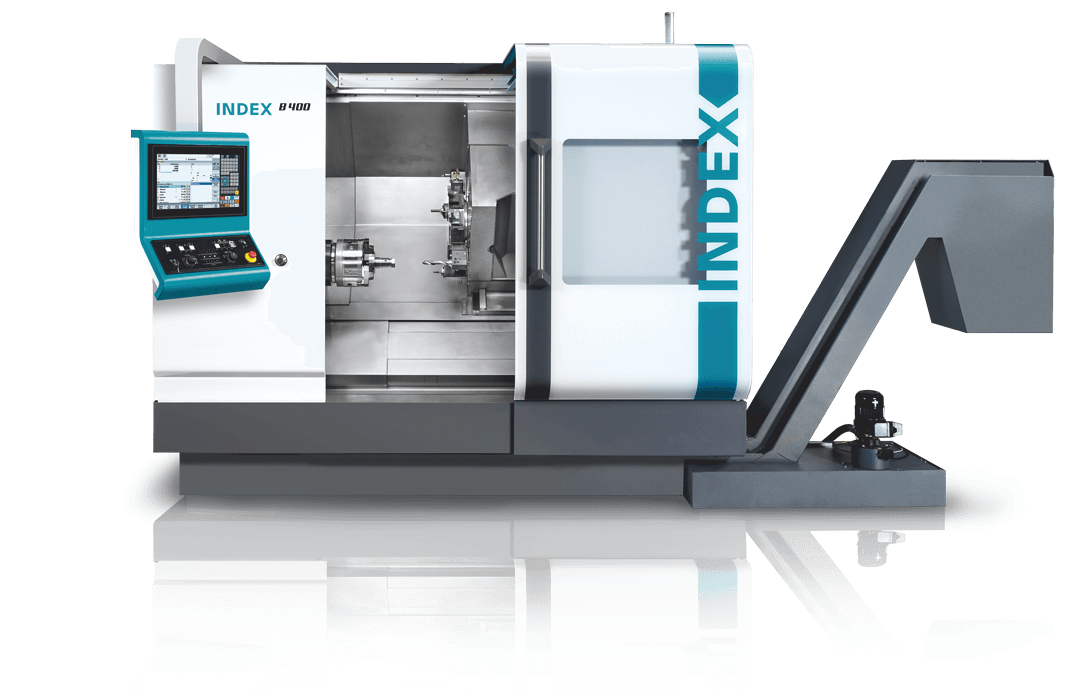

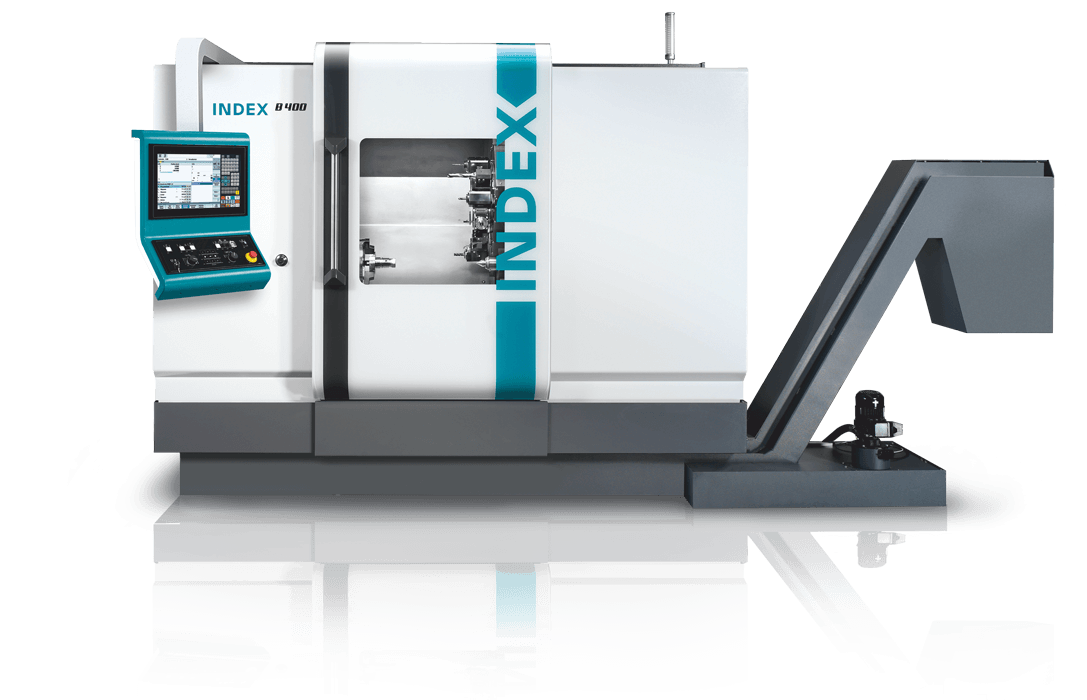

INDEX B400 - Universal turning at the highest level

Universal lathe for precise and powerful machining

Machine highlights

Your benefits

- Clearly structured and ergonomic work area concept

- Rigid mineral cast bed in 45° monoblock design for high accuracy

- Work spindle with belt drive for high torques

- Bar capacity dia. 82 mm, chuck up to dia. 315 mm

- Orthogonal, linear Y-axis for high accuracy

- NC tailstock with electrically controlled axis

- Already included: the operating system iXpanel i4.0 ready with 18.5” touch screen - based on Siemens S840D sl

Structured machine design

The INDEX B400 represents a logical further development of proven manufacturing solutions within the INDEX Group. Individually equipped, this new flexible universal lathe takes its place both in tooling and prototyping, but also in production Decades of accumulated know-how is reflected in numerous design details, such as in a pocket in the panel above the mainspindle which ensures collision-free use of long boring bars.

The components

Main spindle

- Bar capacity dia. 82 mm, chuck up to dia. 315 mm

- Speed 4,000 rpm• Spindle power 24 kW (40%)

- Torque 550 Nm (40%)

- Holding brake for indexing the axis

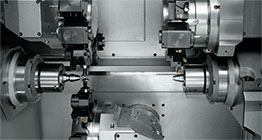

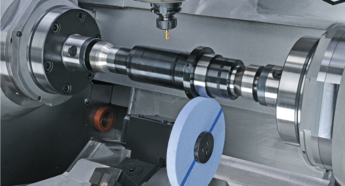

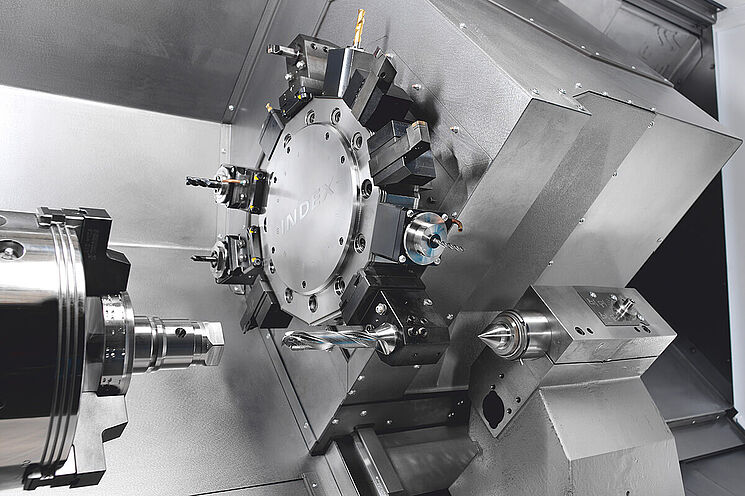

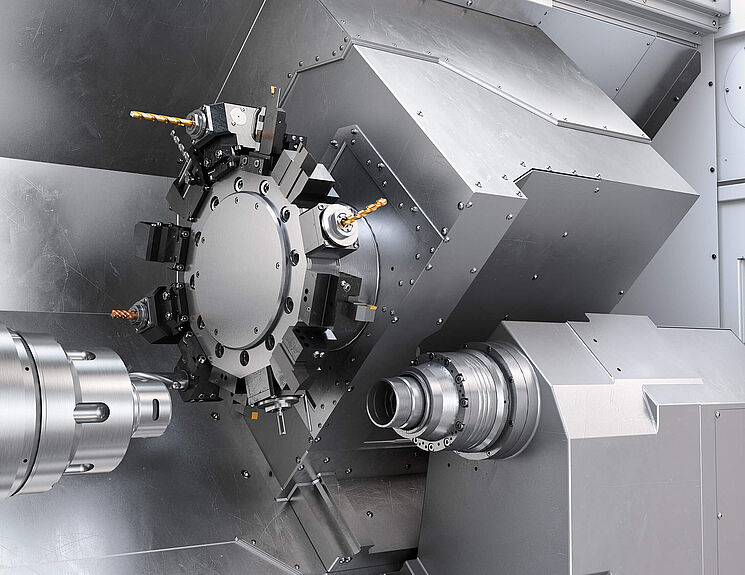

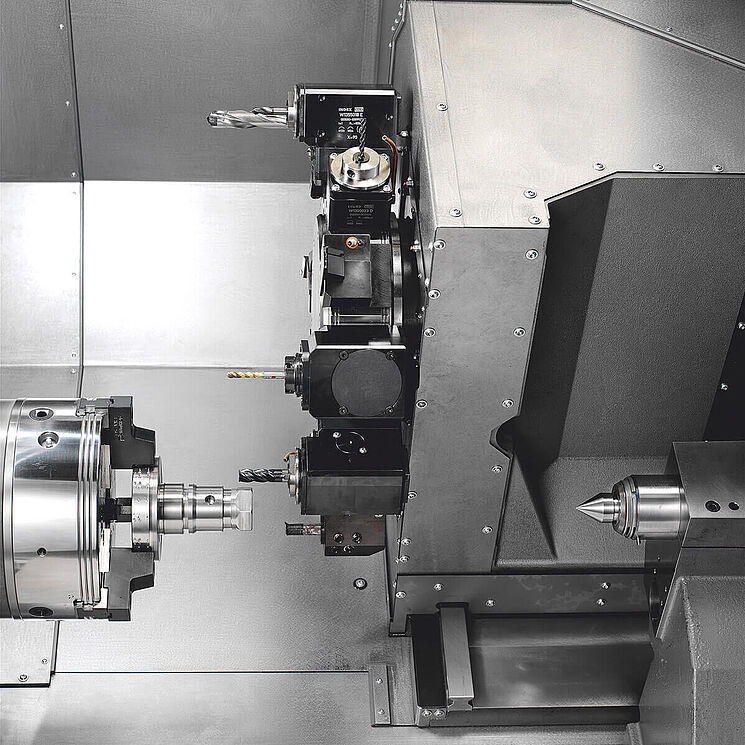

Star turret and compound slide setup / Disc turret

- 18 live tool stations• VDI 30 according to DIN 69880 with patented W-serration

- X 360 mm / Y ±60 mm / turning length Z up to max. 750 mm

- Machining possible up to 70 mm below turning center

- 6,000 rpm, 8.8 kW, 19.5 Nm (25%)

NC tailstock

- electronically freely positionable

- generously dimensioned roller guides

- electronically adjustable pressure force up to 10,000 N

- Cone center MK 5 or SK 30

Counter spindle

- Spindle clearance dia. 65 mm, chuck up to dia. 175 mm

- Speed max. 4,000 rpm

- Spindle power 12 kW (40% duty cycle)

- Torque 119 Nm (40% duty cycle)

- Holding brake for indexing the axis

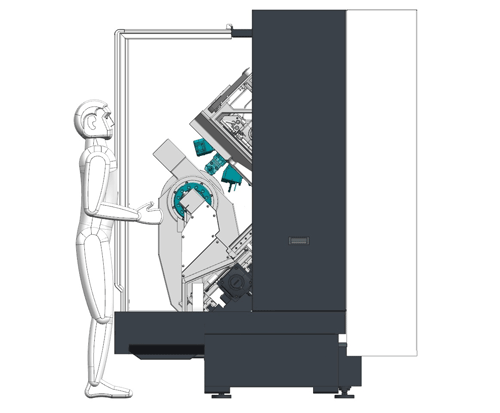

Ergonomic operating concept

The generously dimensioned work area ensures best accessibility for setup of the INDEX B400. Main spindle and tool turret can be accessed easily allowing fast and flexible setup and changeover. The sophisticated work area concept with steep-sloping and smooth covers provides for the ideal chip flow and prevents chip nests.

Highlights

- Fast setup

- Excellent access to thework area

- Good chip flow

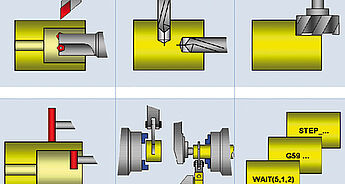

The W-serration

The patented INDEX W-serration for high change and repeat accuracy of the tool.

- Short tooling/setting-uptimes

- High change accuracy bylong fixing grooves

- Extended life of cutting inserts

- DIN 69880-compatible

- Suitable for stationary and live tools