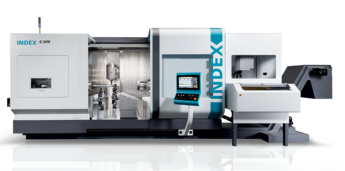

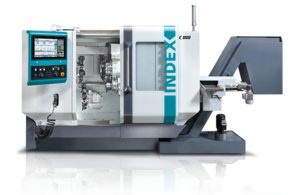

Turning & grinding in perfection

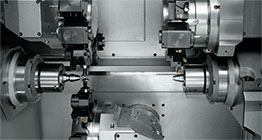

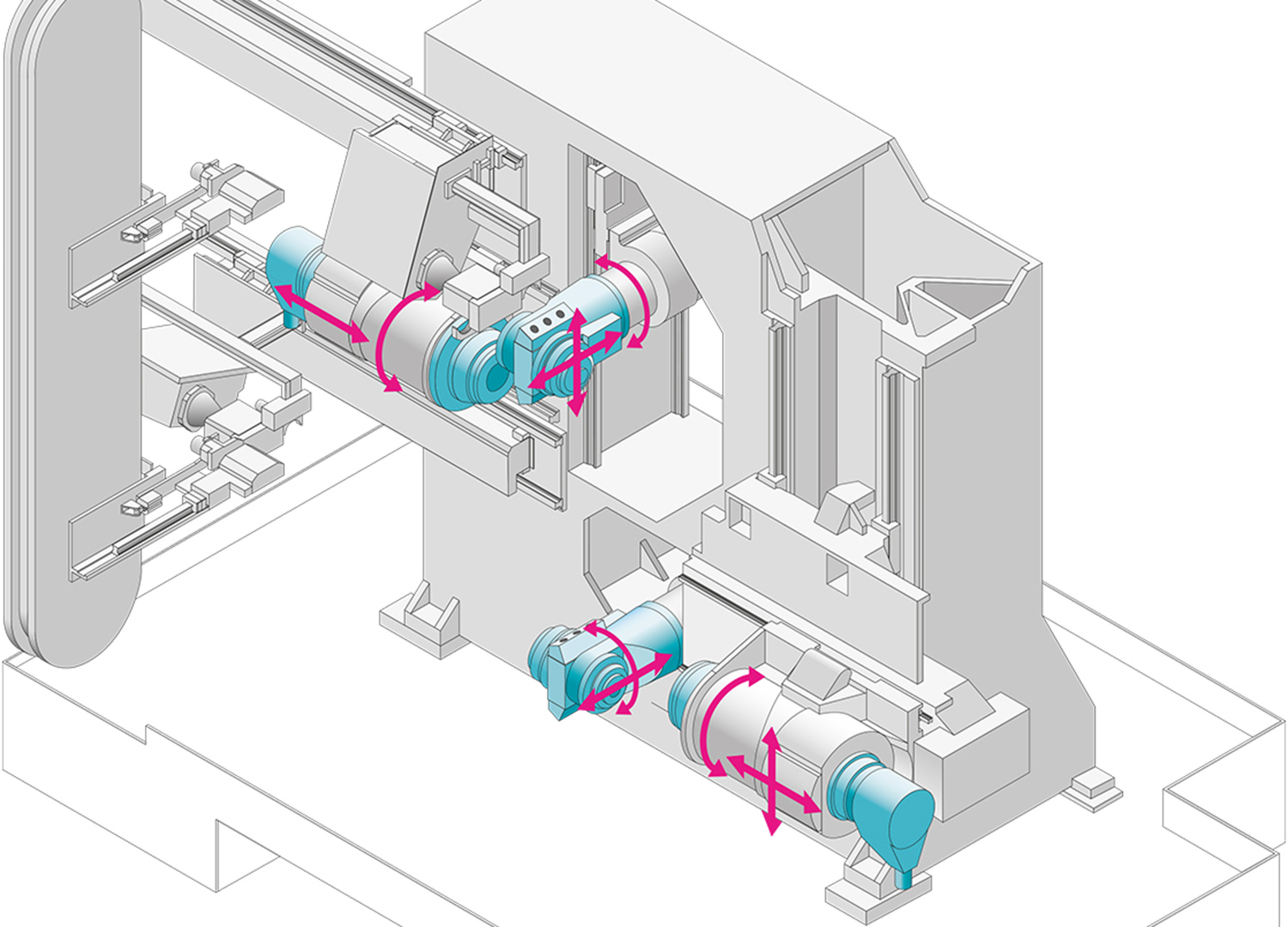

Limitless possibilities in 5 axes

Machine highlights

Your benefits

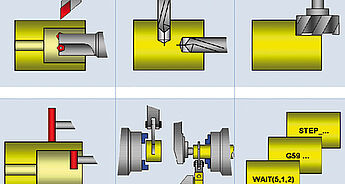

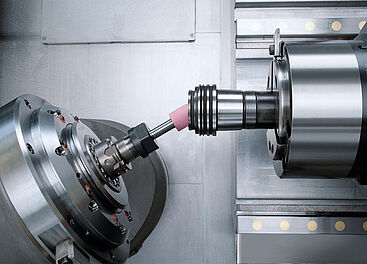

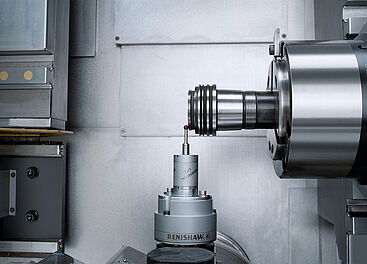

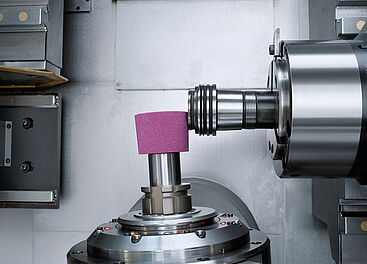

- Grinding with motorized milling spindle

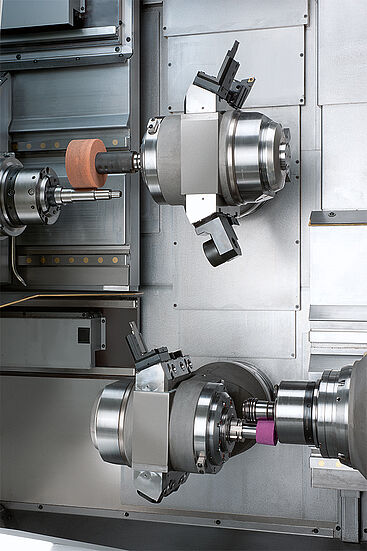

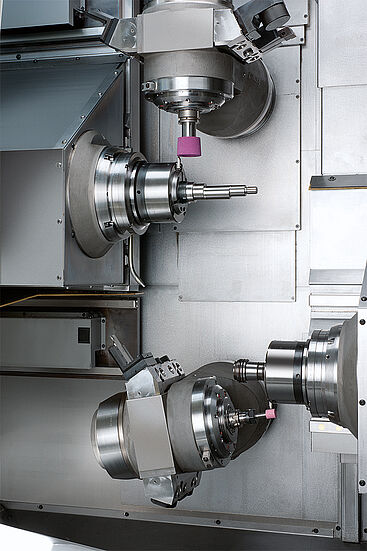

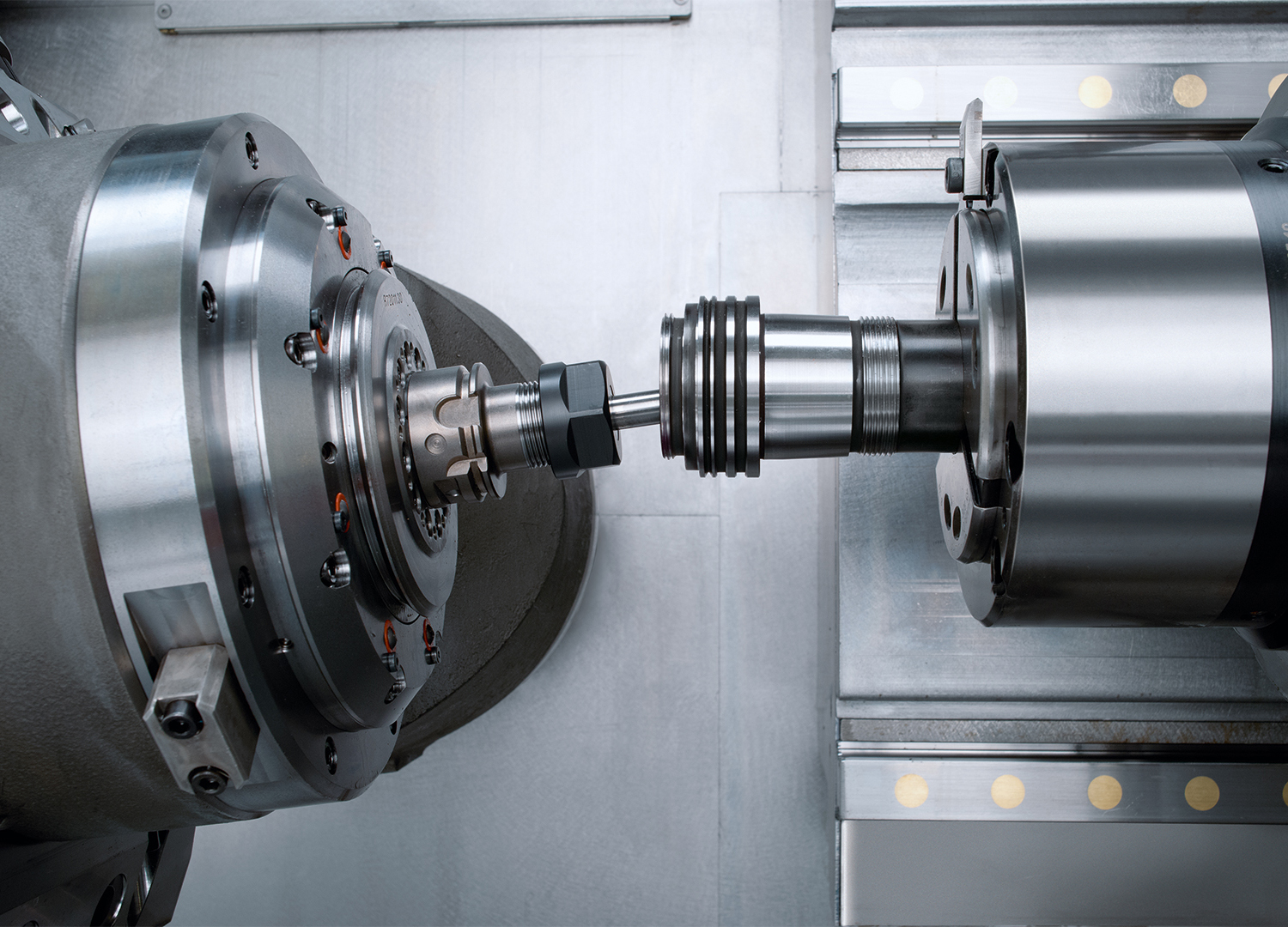

- Front and rear end machining in 5 degrees of freedom

- Large tool pool in the magazine saves set-up time

- High rigidity and precision

- Dressing cycles and wheel contact detection is fully automated

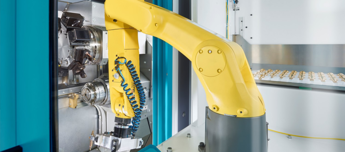

- Automatic loading and unloading by INDEX WHU/WHW workpiece handling unit

- Internal post-process measuring device

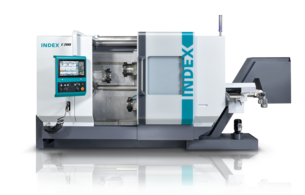

Turn-grind centers R200 & R300 in focus

The machine design

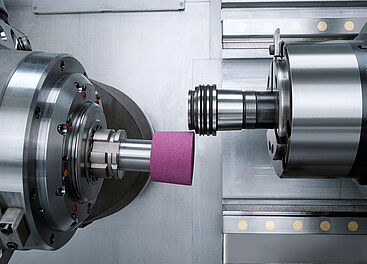

Kinematics perfectly suited for grinding allow simultaneous front and rear end machining in 5 degrees of freedom. This opens up so far unimagined possibilities for internal, external and flat grinding. The magazine’s large tool capacity saves you setup times and always gives you the best tool for the process.

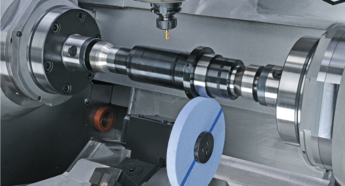

“The results speak for themselves”

Grinding roundness: 0.1 to 0.5 μm

Roughness Ra: 0.1 to 0.4 μm

Roughness Rz: 1 to 3 μm

Grinding Components

| Description | Unit | R200 | R300 |

|---|---|---|---|

| Grinding wheel diameter | mm | 50 (80*) | 63 (160*) |

| Mounting for grinding wheel arbors | HSK | HSK-A40 | HSK-T63 |

| Power (at 100% duty cycle) | kW | 11 | 24 |

| Torque (at 100% / 25% duty cycle) | Nm | 19 / 30 | 65 / 95 |

| Speed | rpm | 18.000 | 9.000 |

*Adjacent magazine stations must remain free