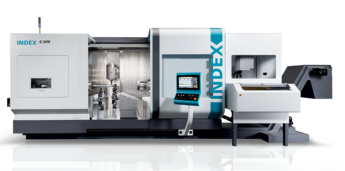

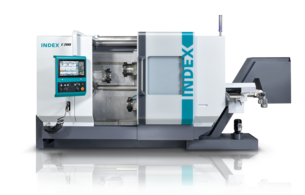

TNL32 Sliding headstock machines – Compact. Precise. Fast.

Three variants with measurable benefits for your production.

Machine highlights

Your benefits

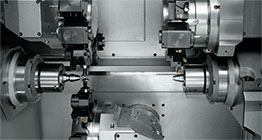

- Simultaneous machining with up to 3 tools (each tool with variable feed rate)

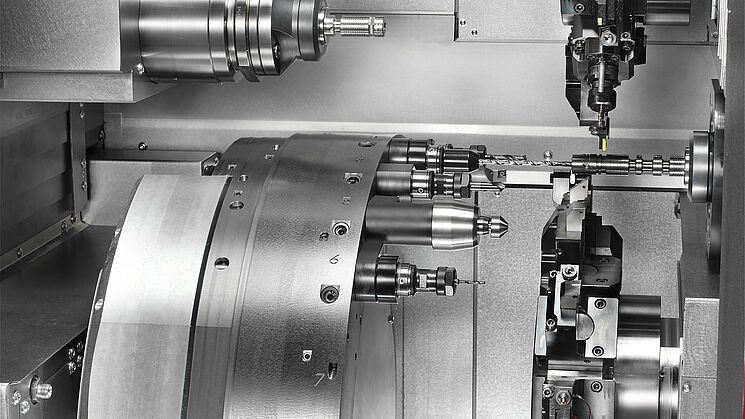

- Clearly structured work area with large axis travels and wide tooling circles

- Excellent accessibility through a large sliding cover

- Easy changeover between sliding and fixed headstock operation

- Very compact machine design with small footprint

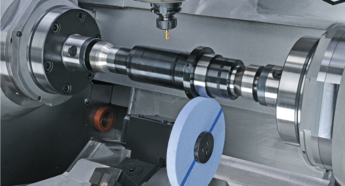

- Highest precision due to thermal symmetric machine structure

- DualDrive: New tool drive system from TRAUB

TNL32 in focus

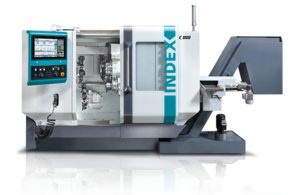

The 3 versions of the TNL32

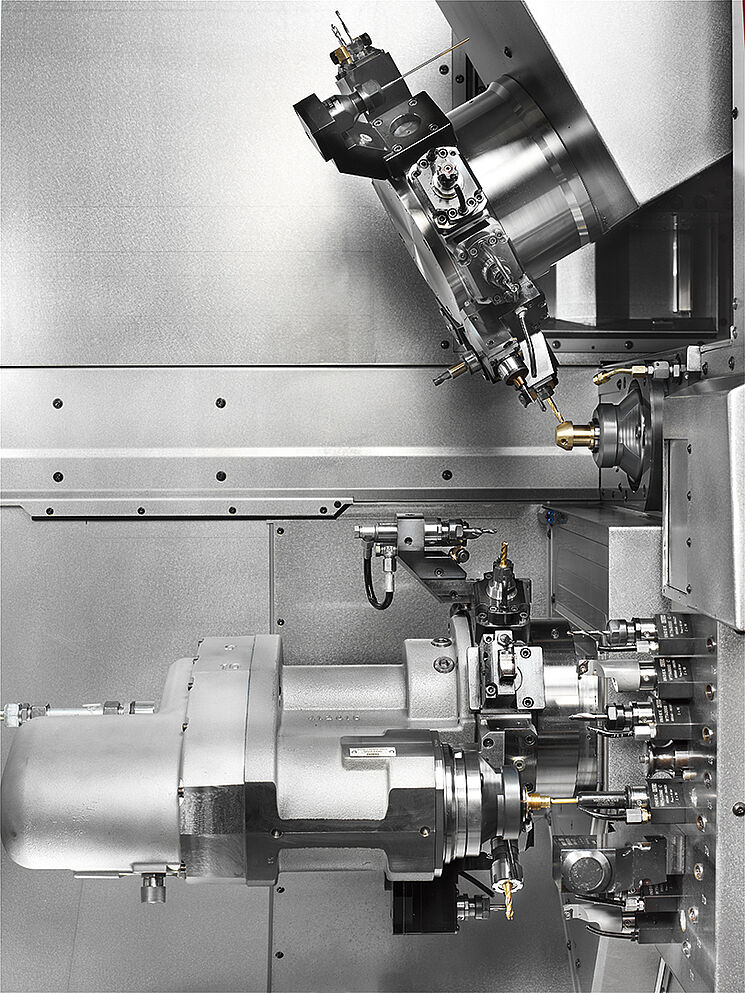

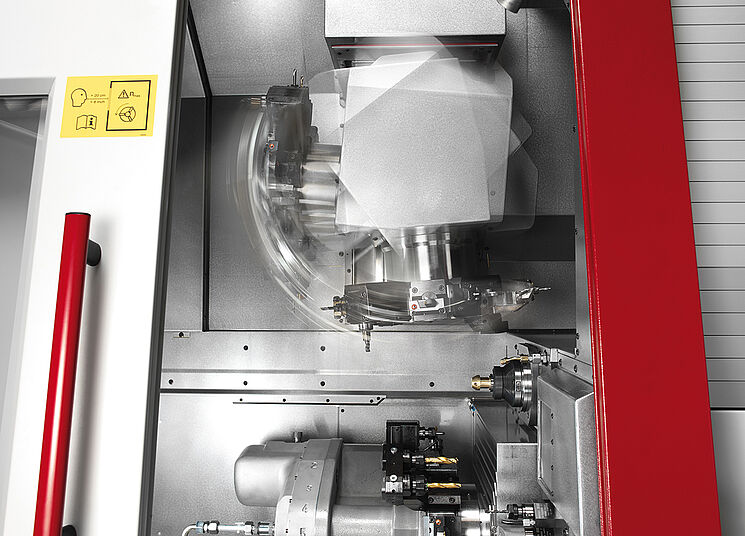

TNL32-7B

Equipped with B-axis

The TNL32-7B version is an expansion stage, which expands the range of applications by the most demanding machining tasks. With the additional B-axis in the upper tool carrier, which can pivot by 100°, highly complex parts and complicated contour elements can be machined that also require additional operations such as milling, drilling, lateral drilling or transversal threading at any preferred angular position. For parallel main spindle operations, angled tool holders were necessary so far with "normal" turret positioning – now the turret simply pivots.

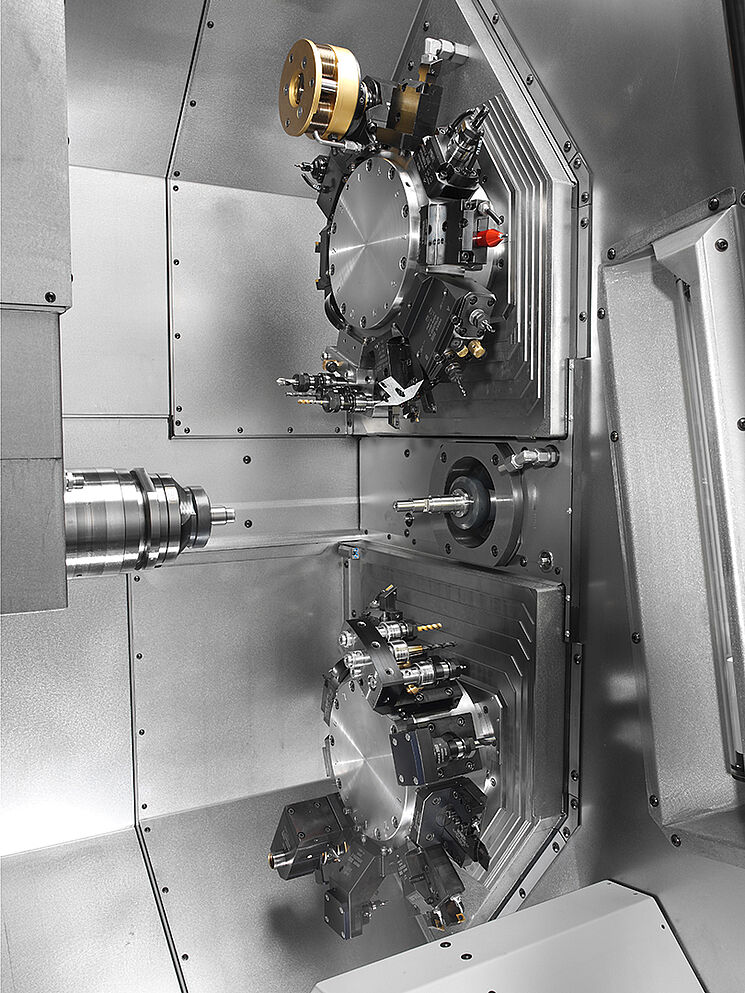

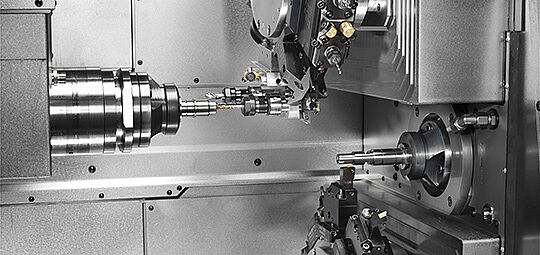

TNL32-9

Counter spindle for more flexibility

The TNL32-9 has an autonomous counter spindle and 9 NC axes. This concept offers you comprehensive machining options up to a bar capacity of 32 mm. A counter spindle identical to the main spindle is mounted on a separate X-Z compound-slide, providing a Z travel range of 300 mm. 140 mm of X-axis stroke ensure simultaneous internal machining on the main and counter spindles.

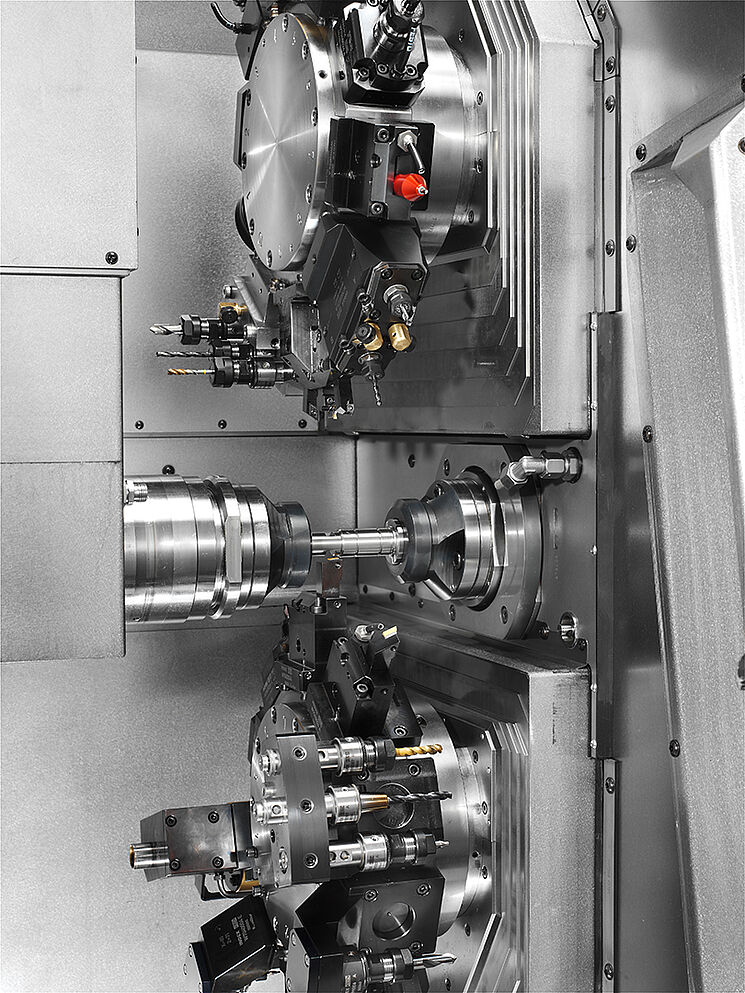

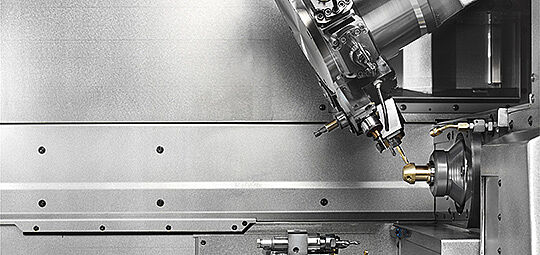

TNL32-11

Front working attachment for more productivity

Two turrets, an additional front working attachment, and an autonomous counter spindle allow you to machine with three independent subsystems. The front working attachment – features & benefits:

- Y-axis function

- Large tool pool:

4X stationary tools, 4x live tools

Max. power 3.4 kW, max. speed 12,000 rpm - Internal coolant supply at each station with max. cutting oil pressure 80 bar

- Deep-hole drilling: max. speed 12,000 rpm, max. cutting oil pressure 120 bar

- Feed force up to 6,200 N

- Tailstock function for bar stock machining

- Workpiece gripper

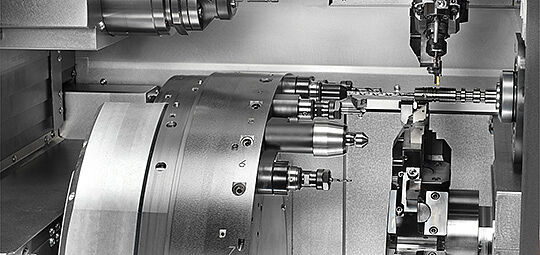

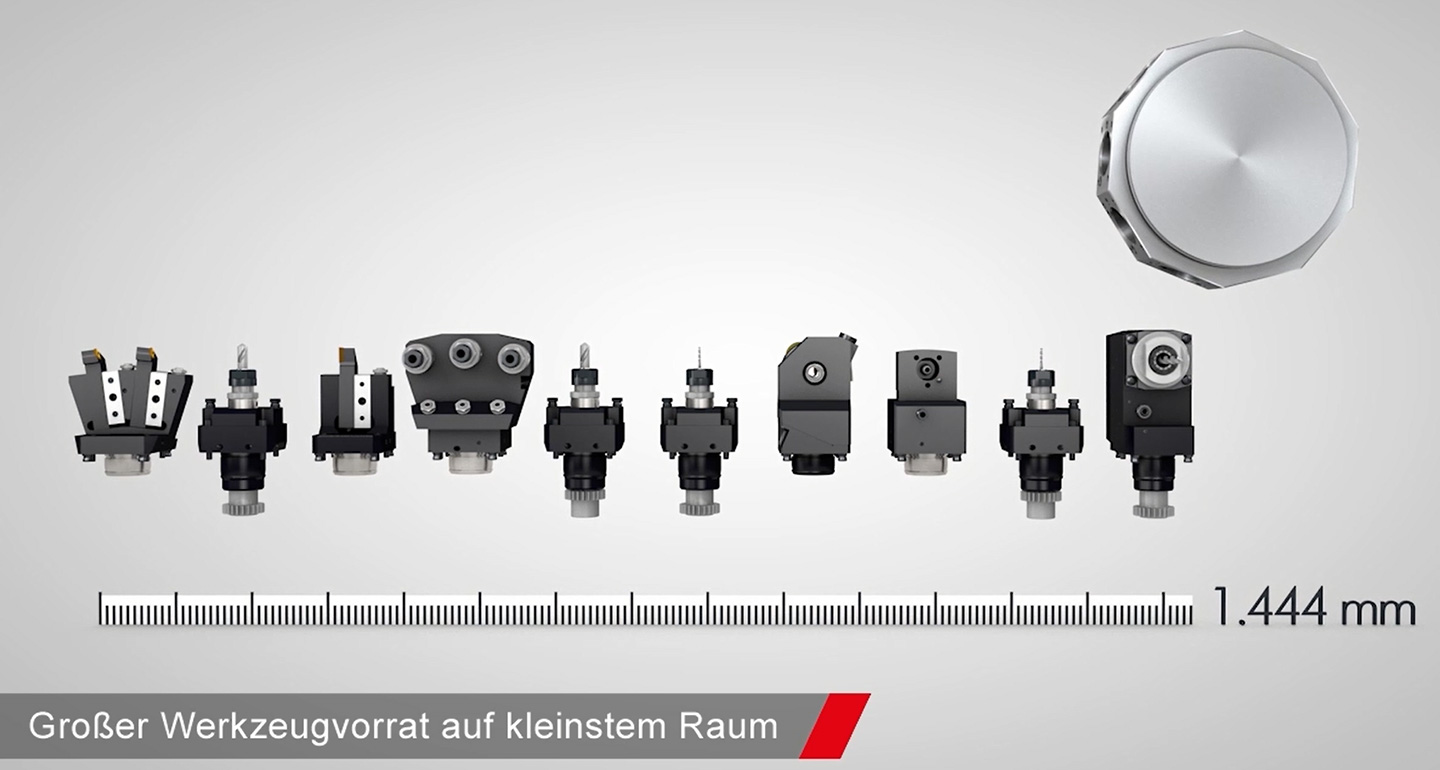

Large tool pool in the smallest space

The tooling circle corresponds to remarkable 1,444 mm of Y-travel unwrapped, beating any linear tool carrier.

The rotating movement of the turrets is performed as an NC axis without mechanical lock. This allows you to position the turret very fast at any angle.