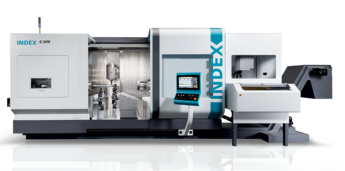

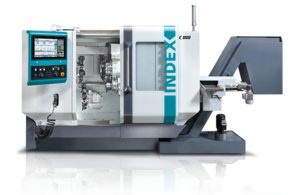

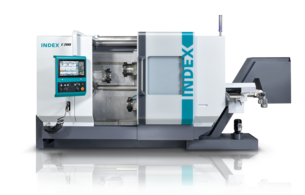

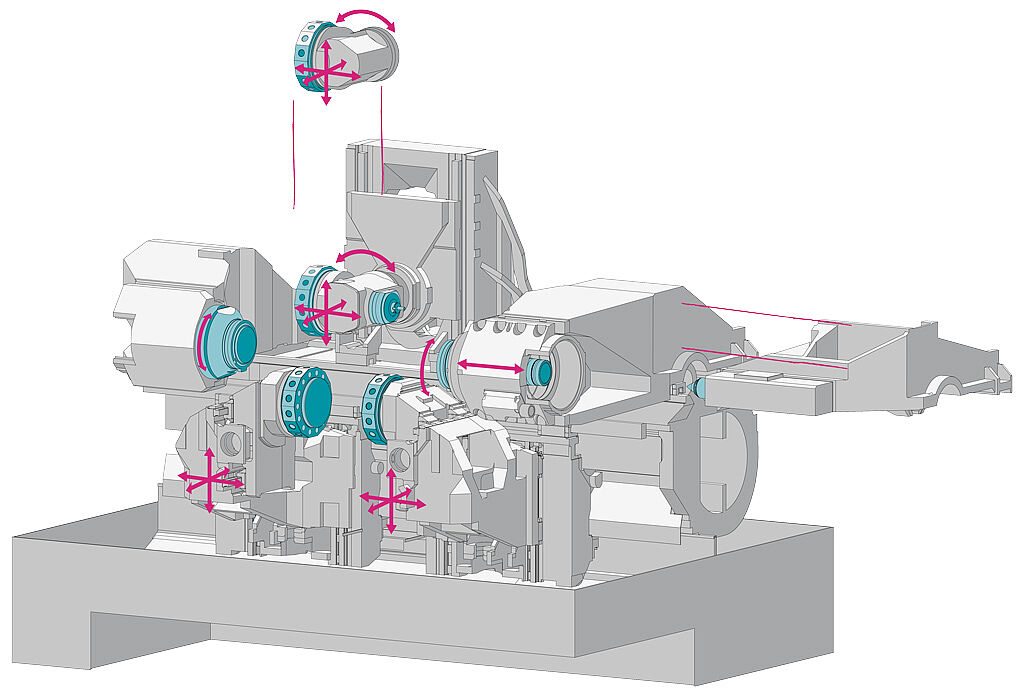

The INDEX G200. Flexible turning and milling - as productive as automatic turning.

The next generation of the turn-mill center with more performance at minimum space.

Machine highlights

Your benefits

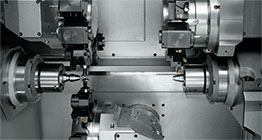

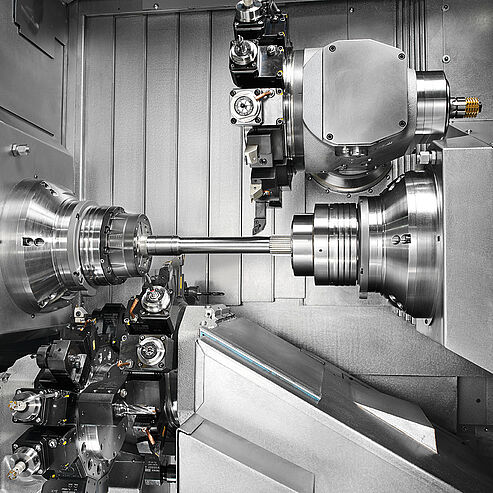

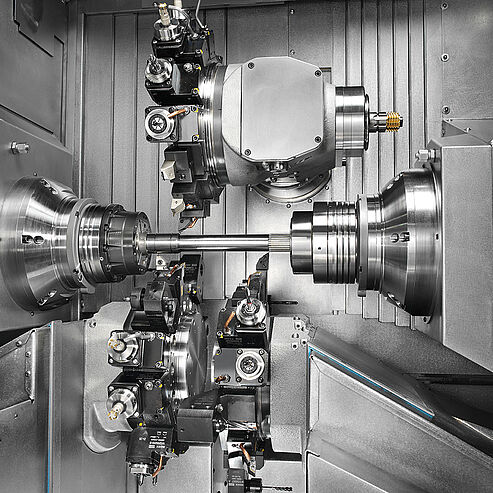

- Up to three tool carriers with Y-axis usable on main and counter spindles

- Simultaneous machining with up to 4 tools possible

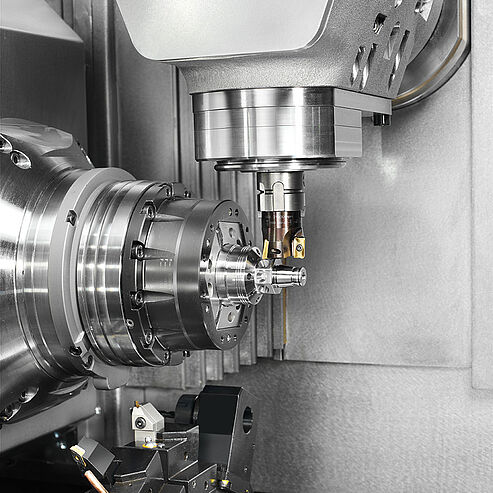

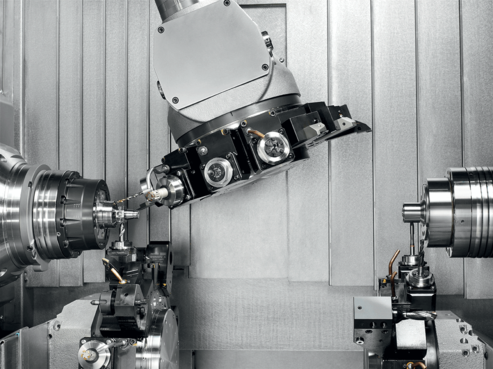

- Powerful and dynamic milling spindle (360° B-axis, max. 7,200 rpm, 22 kW and 52 Nm, HSK-A40)

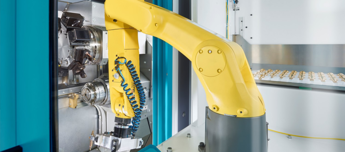

- Economic complete machining of parts as well as of bar stock and as of chuck parts

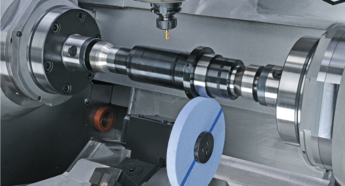

- Incomparably large degrees of freedom in the large work area for turning-milling operations with up to 660 mm turning length

- Excellent ergonomics for quick setup

- Compact foot print an enormous power density for economic manufacturing

G200 in focus

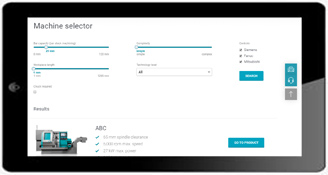

Flexible modular system

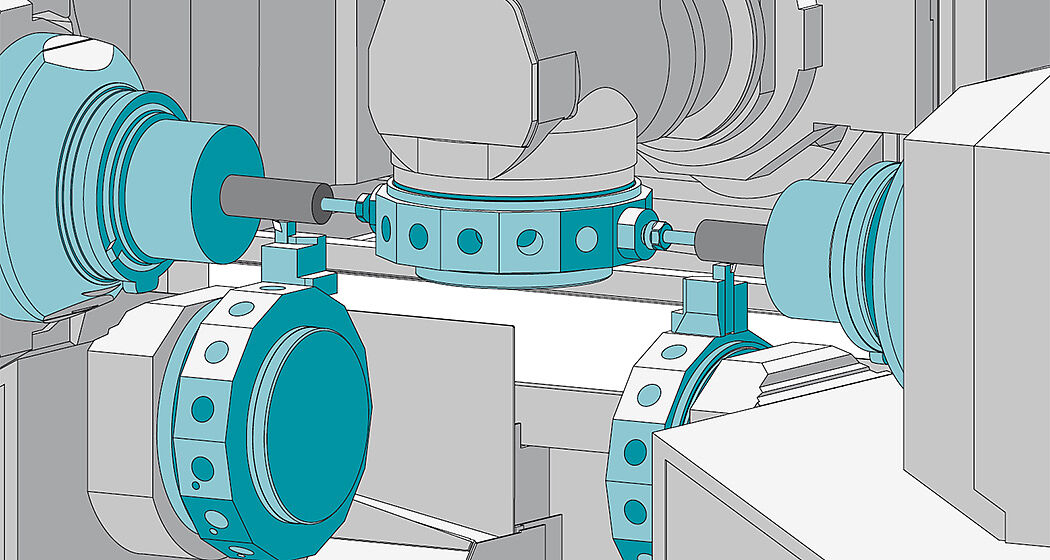

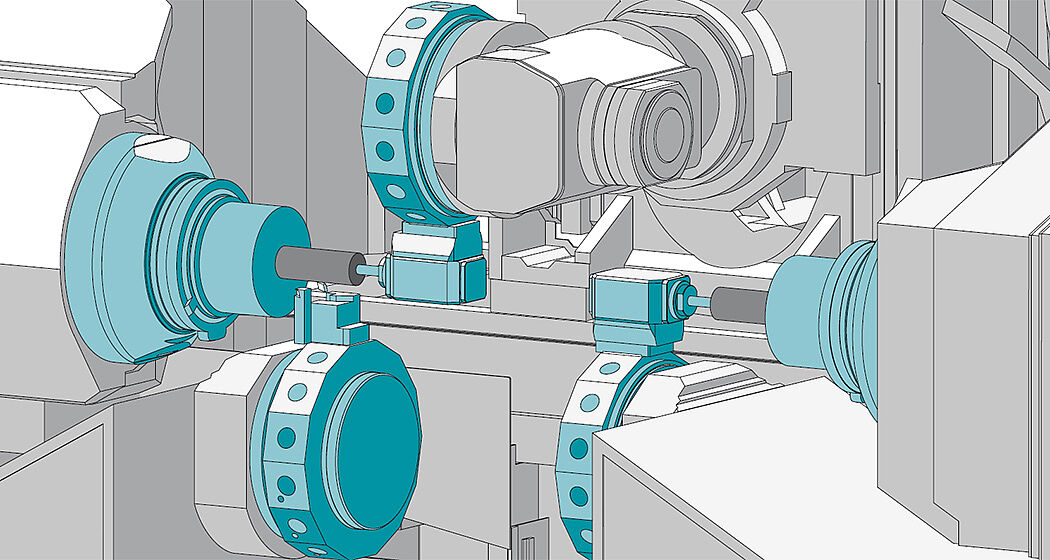

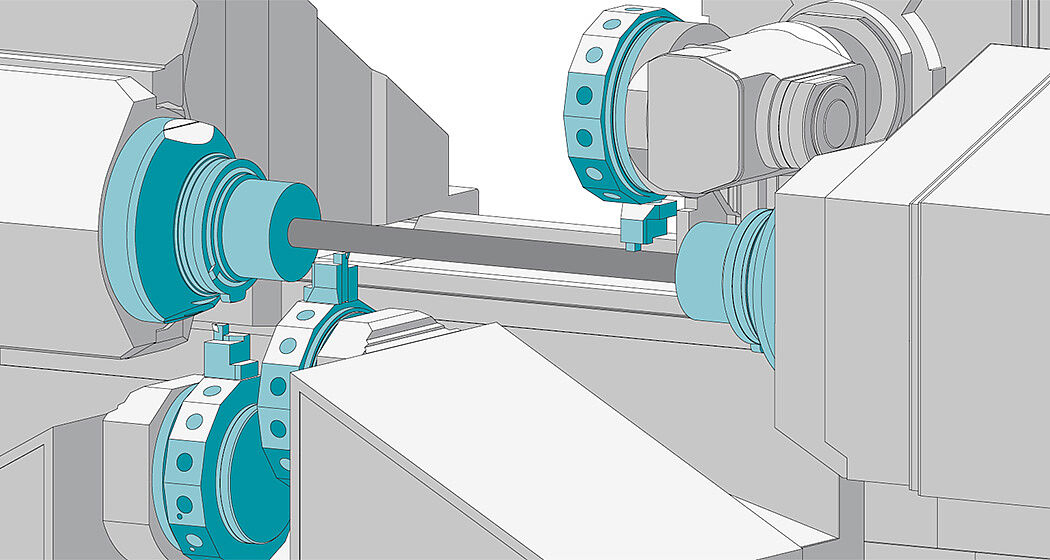

With a high degree of rigidity, thermal and dynamic stability as well as very good vibration-damping properties, the G200 enables production with excellent workpiece qualities. The powerful milling spindle, in connection with the Y/B-axis running in hydrodynamic bearings ensures sophisticated drilling or milling operations – without the use of live tool holders – easy and cost-effective. Configure the turn-mill center INDEX G200 adjusted to your workpiece requirements. Up to three tool carriers with Y-axis and a maximum tool pool of up to 42 stations (VDI25) are usable on main and counter spindle of the turn-mill center. Even a tail stock or a turret steady with a clamping range of 10 to 66 mm are possible within the configuration of the G200.

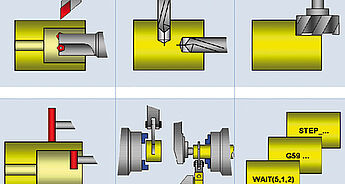

Wide variety of machining options

Incomparably large degrees of freedom in the work area

Economic complete machining

End piece

Material: 44SMn28

Diameter: 39 mm

Length: 92 mm

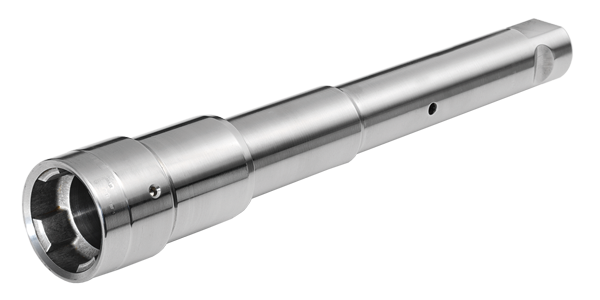

Input shaft

Material: 100Cr6 Diameter: 26 mm Length: 160 mm

Switching shaft

Material: 16MnCr5 Diameter: 60 mm Length: 170 mm