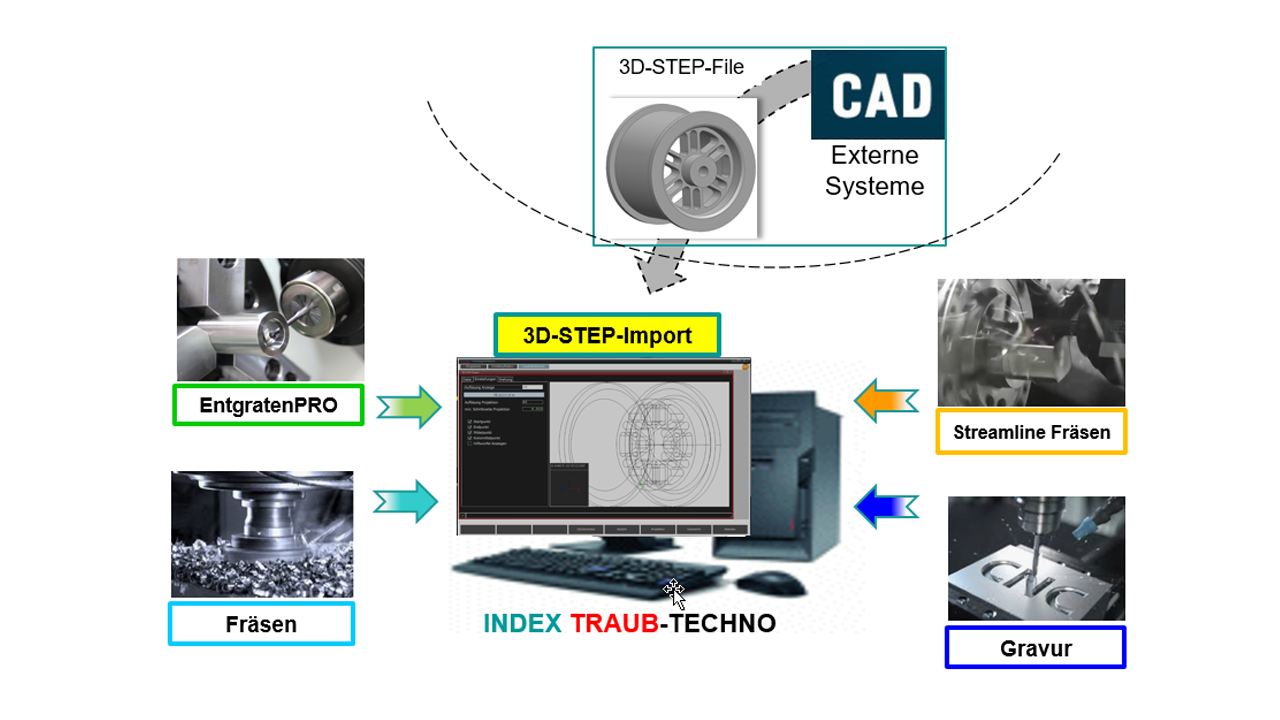

INDEX TRAUB-TECHNO technology packages

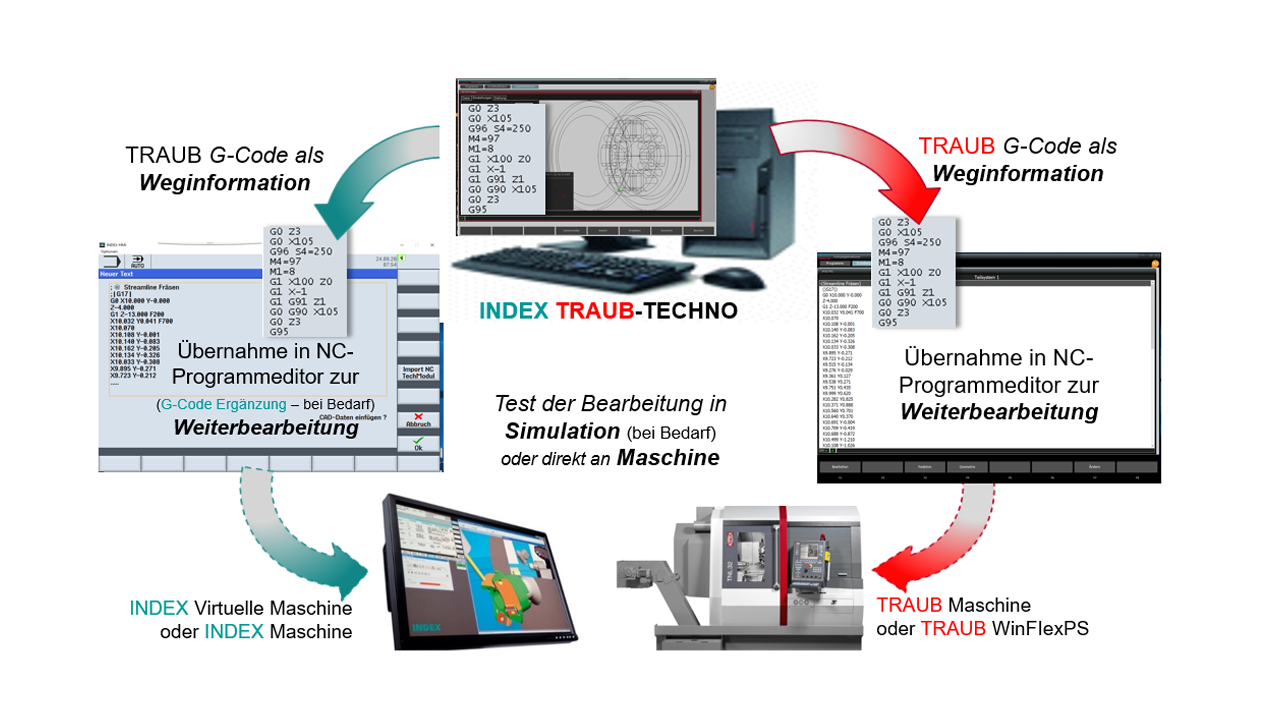

INDEX TRAUB-TECHNO:

PC software for CNC programming of additional machining technologies.

+Technology packages I

(options): Technology packages enable additional technological machining with output of CNC blocks for further processing.

Runs and can be used on a PC independently of INDEX Virtual Machine and TRAUB WinFIexPS

- 3D-STEP Import technology package (SAP 12033646)

- DeburringPRO technology package (SAP 12033647)

- Milling technology package (SAP 12033645)

- Streamline milling technology package (SAP 12033644)

- Engraving* technology package (SAP 12033643)

*IT-TECHNO with “Engraving” technology package is identical to the former WinGravur

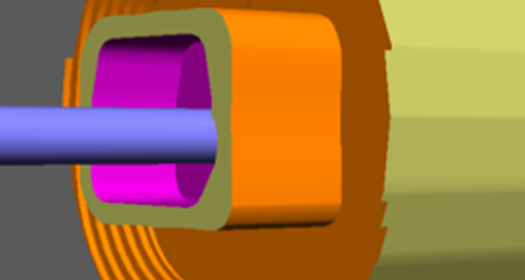

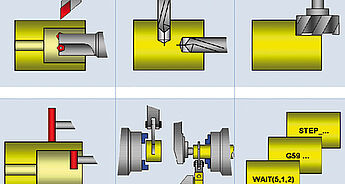

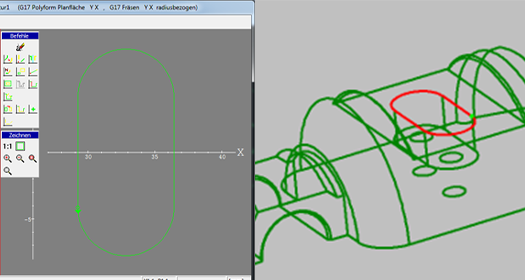

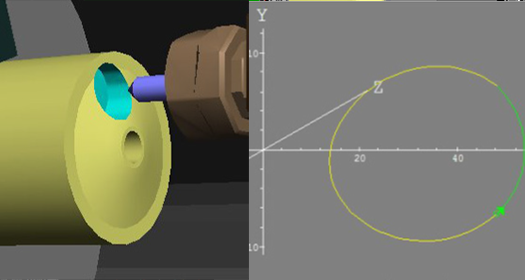

3D-STEP import (option)

With the “3D-STEP Import” interactive function, 3D files can be loaded directly in STEP format (.stp/.step) and opened. The loaded object is displayed as a mesh model.

- Direct transfer of contours from 3D-STEP data to the INDEX TRAUB-TECHNO module

- Easy and fast alignment of the position of the 3D model to the next rectangular plane

- Zero point is set by snapping and clicking on a desired existing point

- Automatically generated contour from contiguous geometrical elements

- Flexible use of the contours for workpieces, blanks, cutting tool edge shapes, etc.

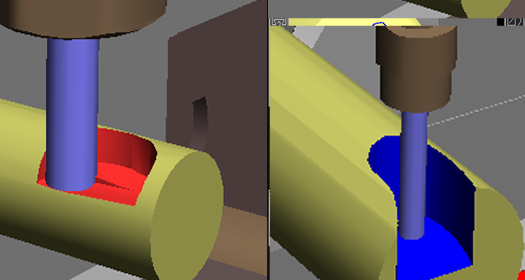

DeburringPRO (option)

Deburring complex contours

- Interactive function for deburring edges and openings

- Calculation functions for full radius cutters or chamfer cutters

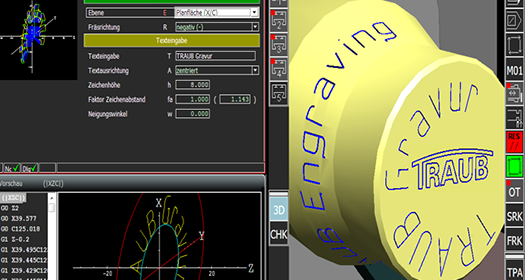

Engraving (option)

Engraving lettering and logos

- Graphics-based interactive support on face, cylinder sleeve, or taper sleeve

- Marking of workpieces with sequential numbers

- Marking of logos

- Adjustable font size, position, spacing, etc.

- Font settings, e.g., italic, mirror font

- Graphics-based machining preview directly upon input

Milling (option)

Advanced milling operations

- Helical contour milling with simultaneous axial and radial infeed

- Trochoidal milling for optimum removal rate with the full cutting edge

Streamline milling (option)

Streamline milling

(high-speed milling)

- Milling of contours, taking into account highly efficient machining strategies

- Increased tool life and surface quality thanks to constant chip volume

- Supports machining of Torx profiles (T6-T100) with streamline strategy