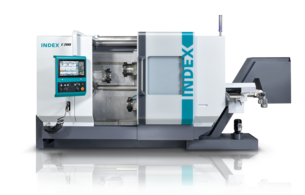

Excellent turning results with the bar loader MBL65

Always well loaded - Intelligent loader assures short set-up times, fast bar change and a precise guidance of the bar

Highlights Bar loader MBL65

Your benefits

- Shortest setup times through good accessibility and quick-change guide bushings

- Ergonomical loading height - loading during machining possible

- Mineral cast bed for a very high degree of stiffness and damping

- Outstanding smoothness and accuracy

- Purely electrical, thus no hydraulic and pneumatic connections required

- Shorter design than comparable magazines

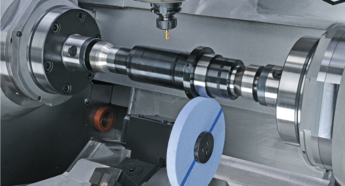

- High surface quality, also for profile materials

MBL65 in focus

Bar loader for best turning results

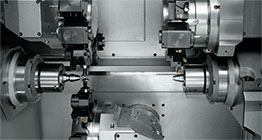

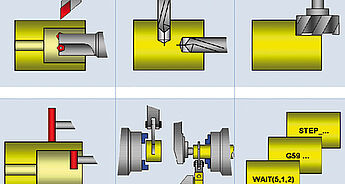

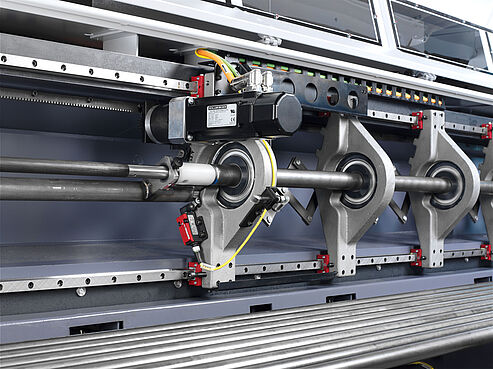

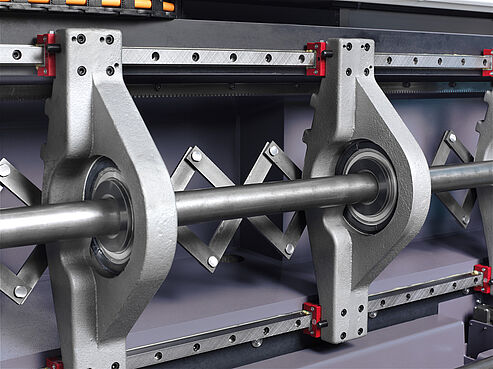

- Backlash-free guidance of the bar in rolling bearings, with diameter-specific plastic sleeves

- Top machining results in terms of surface and tolerances – even with shaped material

- Precise alignment of the bar stock to the spindle center

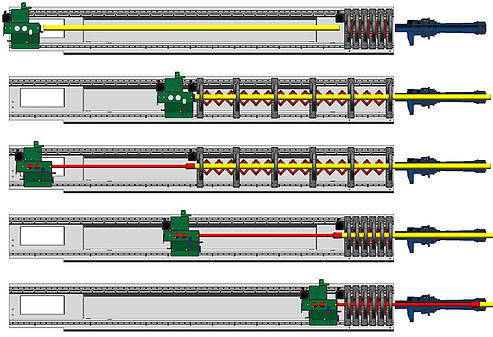

- Fast bar change through intelligent process flow and fast axis movements

- Automated measurement of bar length

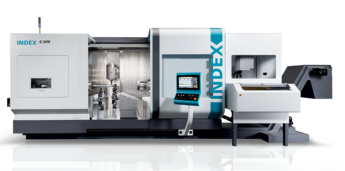

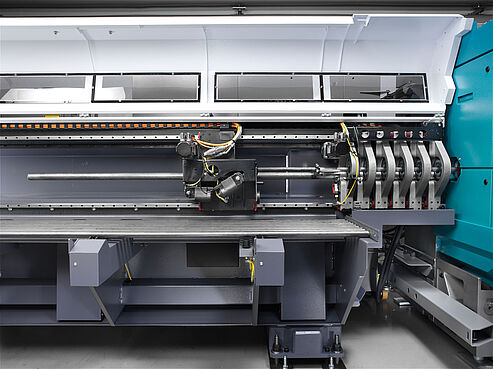

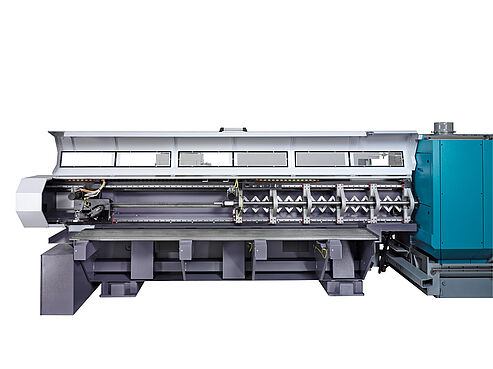

The INDEX MBL65 is available in two different sizes. The MBL65 version 3200 (weight approx. 2200 kg) is suitable for a bar length of 1500 mm to 3200 mm and requires a footprint of approx. 4245 mm in the longitudinal direction. The larger version 4200 (bar length 1700 mm to 4200 mm, weight approx. 2700 kg) requires approx. 5300 mm footprint in the longitudinal direction.

The bar loading magazine MBL65 can hold round bar stock from 10 mm to 65 mm diameter. For hexagon bars a width of 55 mm, for square bars a width of 46 mm is the upper limit. The servo motor for the bar feed unit has a feed force of 1500 N. Traversing speeds are up to 50 m/min in rapid traverse and up to 30 m/min path velocity on initial insertion of the bar stock.

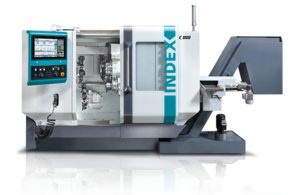

Central element: the vertical base support

To consistently position the MBL65 with top performance, the INDEX developers did not just do a “facelift” but completely redesigned the bar loader.

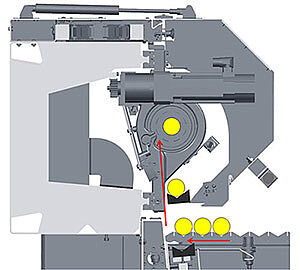

The bar loader was thus equipped with a mineral cast base arranged vertically. Users benefits from excellent damping qualities and exceptionally easy accessibility. The MBL’s mineral cast base is mounted on concrete carriers, which allow the loader height to be adjusted to the spindle height of the lathe.

Linear guides are now attached to the support at the front, replacing the previous circular guides of the slidable lattice grate. The six bearing plates run on them with increased stiffness.

High-speed setup

If a material change with a new diameter is required, the manual conversion work is kept to a minimum. All the operator has to do is to replace the plastic bushings (improved gripping properties) in the six bearing plates and to change, if necessary, the bar pusher rod or its bar-specific head. INDEX provides three bar pusher rod diameters for a broad range of bars up to 65 mm in diameter.

In total, the setup process of the bar loader – due to improved accessibility, less change parts and a semi-automated approach – will take less than 7 minutes, including setting up the spindle reduction and the spindle collet.

| Machine type | Can be combined with MBL65 | Expendable with other bar loaders |

|---|---|---|

| INDEX ABC | ✓ | ✓ |

| INDEX C100 | ✓ | ✓ |

| INDEX C200 | ✓ | ✓ |

| INDEX B400 | - | ✓ |

| TRAUB TNA300 | - | ✓ |

| TRAUB TNA400 | - | ✓ |

| TRAUB TNA500 | - | ✓ |

| TRAUB TNA600 | - | ✓ |

| INDEX G200 | ✓ | ✓ |

| INDEX G220 | ✓ | ✓ |

| INDEX G420 | - | ✓ |

| INDEX R200 | - | ✓ |

| INDEX R300 | - | ✓ |

| TRAUB TNX65 | ✓ | ✓ |

| TRAUB TNL12 | - | ✓ |

| TRAUB TNL20 | - | ✓ |

| TRAUB TNL32 | - | ✓ |