Energy Solutions

High-precision and profitable manufacturing solutions for the Energy Sector

Rely on experience and expertise

In a world increasingly reliant on sustainable energy sources, CNC machine tools play a crucial role in manufacturing highprecision components for a wide range of energy technologies.

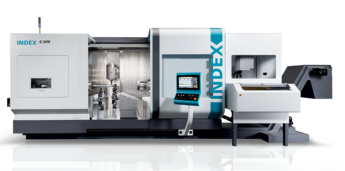

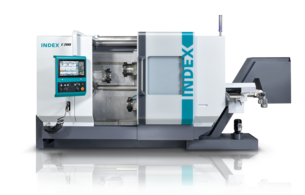

With INDEX automatic production lathes, swiss/fixed-headstock automatic lathes and turn-mill centers, you can not only produce complex geometrical shapes with micron-level precision, but also work with a wide variety of materials—from aluminum alloys and high-strength steels to titanium.

The advanced technology of our products, combined with the ongoing digitization and networking of machine tools, boosts your production efficiency, reduces downtime, and enhances flexibility. Step into the world of INDEX machine tools and discover the possibilities that pave the way to a cleaner, more reliable, and more efficient energy supply.

Quick Navigation - Energy Solutions

Manufacturing of drive and gear components for wind turbines, such as:

- Bearing bushings and hubs

- Shafts

- Large gears

Manufacturing of components for gas power generation and exploration, such as:

- Turbine disks

- Injector nozzles

- Drill heads

Manufacturing of components for solar and hydropower use, such as:

- Slot nuts

- Connectors

- Compressor pistons

Manufacturing of components for pumps and valves, such as:

- Fittings

- Valve technology

- Radial compressors

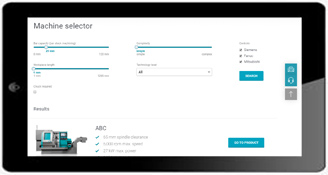

Find the best manufacturing solution for peak performance

Wind Energy Technology

High-precision and profitable manufacturing solutions

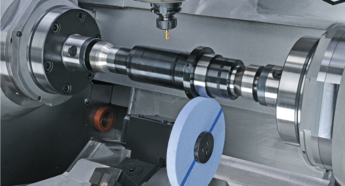

The production of components for wind turbines requires high-precision machining technologies. Learn more about the innovative lathes and processes that allow you to produce components with exceptional accuracy and efficiency, and find out how our solutions help you achieve optimal results.

Your advantage: high precision and process reliability thanks to flexible complete machining

Wind Energy Technology - Sample Parts

Precision machining of gas power components

Powerful complete machining

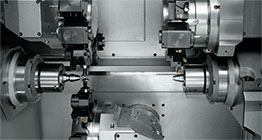

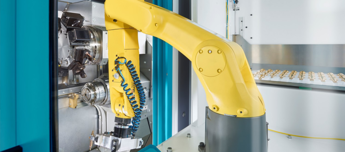

INDEX machines enable efficient and precise machining of components like turbine blades and disks, rotors, and other parts critical to the performance and reliability of gas power plants.

By combining various machining technologies, INDEX machines are the ideal choice for producing complex workpieces that meet the industry’s high standards.

Your advantage: maximum efficiency through economic complete machining of complex parts.

Gas Power Components - Sample Parts

Economical manufacturing in the solar and hydropower sectors

Precise, fast, and efficient

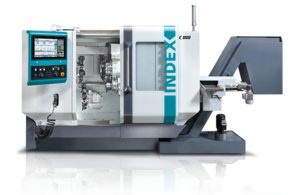

INDEX and TRAUB lathes enable precise machining of parts like mounting systems, brackets, rotor shafts, and other critical components essential for the functionality and efficiency of solar and hydropower systems. Their versatility allows them to handle a wide range of materials, including metals, plastics, and composites. The machines’ efficiency and accuracy help reduce production costs while maximizing the quality of the parts produced.

Your advantage: fast and precise part production using swiss and fixed-headstock turning, with up to 4 tools simultaneously.

Solar and Hydropower - Sample Parts

High Precision and Flexibility in Valves, Pumps and Compressors

Tight tolerances and absolutely no burrs

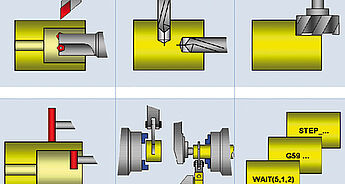

In fluid technology, hydraulics, and pneumatics, precision parts are required that involve not only turning and milling but also cross-drilling, deep-hole drilling, and multi-edge contours. The corresponding components are often designed for flow optimization and must meet the highest standards of tightness. The tasks to be performed require execution of demanding drive and control operations with fluids and gases.

Your advantage: low unit costs for versatile machining and high-volume production.