Brave new INDEX world

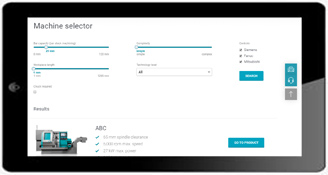

INDEX will present the first apps of its iXworld cloud-based platform at AMB 2018. Designed to profitably support the user in many areas, the new apps will be accessible through the iXplore, iXshop, iXservices and iX4.0 modules. Using these, the user can call up digital support for the entire process chain, from gathering information during the purchasing process to operating the machine to service and procurement of spare parts.

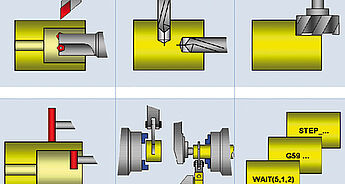

INDEX has been offering advanced digital solutions for years, most notably through the simulation and programming software “Virtual Machine / VMPro” and TRAUB “WinFlexIPS”. Based on the real machine geometry and software, but separate from ongoing production, these simulations allow new start-ups and workpiece machining to be virtually planned, tested and even pre-optimized in real time. They take into account the automation provided in the working area, with one-hundred percent transferability into the real machine. The iXpanel operating system, which has been offered for INDEX and TRAUB machines for some time, will also be presented in detail at the AMB trade fair. iXpanel provides a high level of convenience and enables networked production.

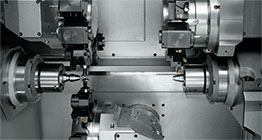

Demonstrations of polygon turning and high-speed whirling technologies are likely to draw the attention of booth visitors. In addition to showcasing exceptional performance of the machines, they will also feature the new ChipMaster chip breaking software.

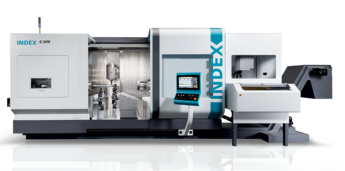

Seven INDEX and TRAUB machines will be on display at the trade fair booth, representing the foundation for the entire new INDEX world. The highlight will be the INDEX G420 – a completely redesigned special category of a turn-mill center, which is characterized by extraordinarily high inherent stability, a very favorable ratio of working area to external dimensions, and a user-friendly, ergonomic design. The INDEX G420 alone is worth a visit, as its exceptional performance is especially apparent in person.

This also applies to the unique INDEX MS22-L, a CNC multi-spindle automatic lathe that can be used to efficiently produce slim components with high process reliability. Unlike any other machine in the world, the INDEX MS22-L provides a Swiss-type function in a sliding guide bushing version.

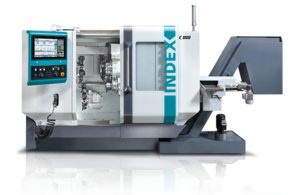

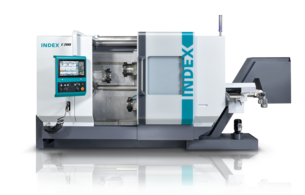

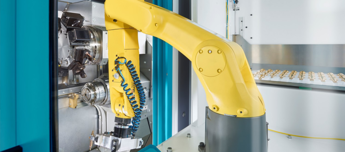

The INDEX C200 shows just how far the company’s automation offering has progressed. The automatic production lathe – in a new, user-friendly design – will be shown at AMB with the iXcenter robot cell that includes vertical pallet storage, which supports fully automated operation. iXcenter, like other automation equipment, can optionally be integrated into various INDEX and TRAUB production machines.

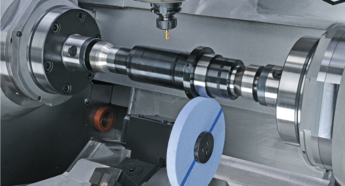

Also on display will be the INDEX B400, which is designed for precise and powerful machining of flange and shaft parts in small batches starting from a quantity of one. Other attractions include the INDEX MS40-8 multi-spindle automatic lathe. With eight motorized spindles, it can process both complex and simple bar and chuck parts in the shortest cycle times.

The TRAUB TNL20 sliding/fixed headstock automatic lathe is available with different equipment levels. On display at AMB will be the TNL20-9B, which – thanks to the additional B-axis in the upper tool carrier – can be used at any angle position for machining of complex parts and complicated contour elements. The same applies to the TRAUB TNL32-7B sliding/fixed headstock automatic lathe with 32 mm bar clearance, 7 linear axes and an additional B-axis.

More machines will be on display outside the INDEX booth: At the students’ booth in the atrium, an INDEX G200 turn-mill center will demonstrate its capabilities. The milling spindle with HSK-A40 tool holder, in conjunction with the hydrodynamically mounted Y/B axes, guarantees reliable performance in demanding drilling and milling operations. At the tool manufacturer Paul Horn GmbH (Hall 1, Booth J18), the INDEX R200 turn-mill center will show that 5-axis machining on the front and rear of workpieces can be applied to an extremely large variety of parts and significantly increase productivity.